LASER MACHINES

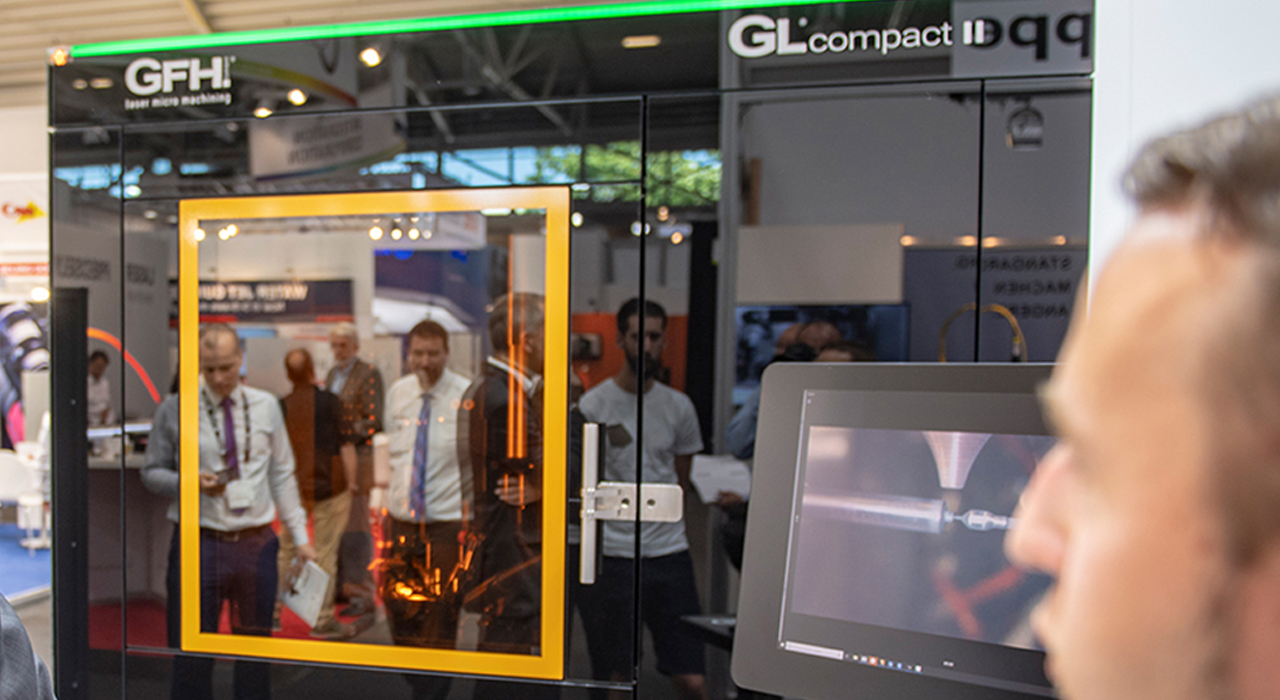

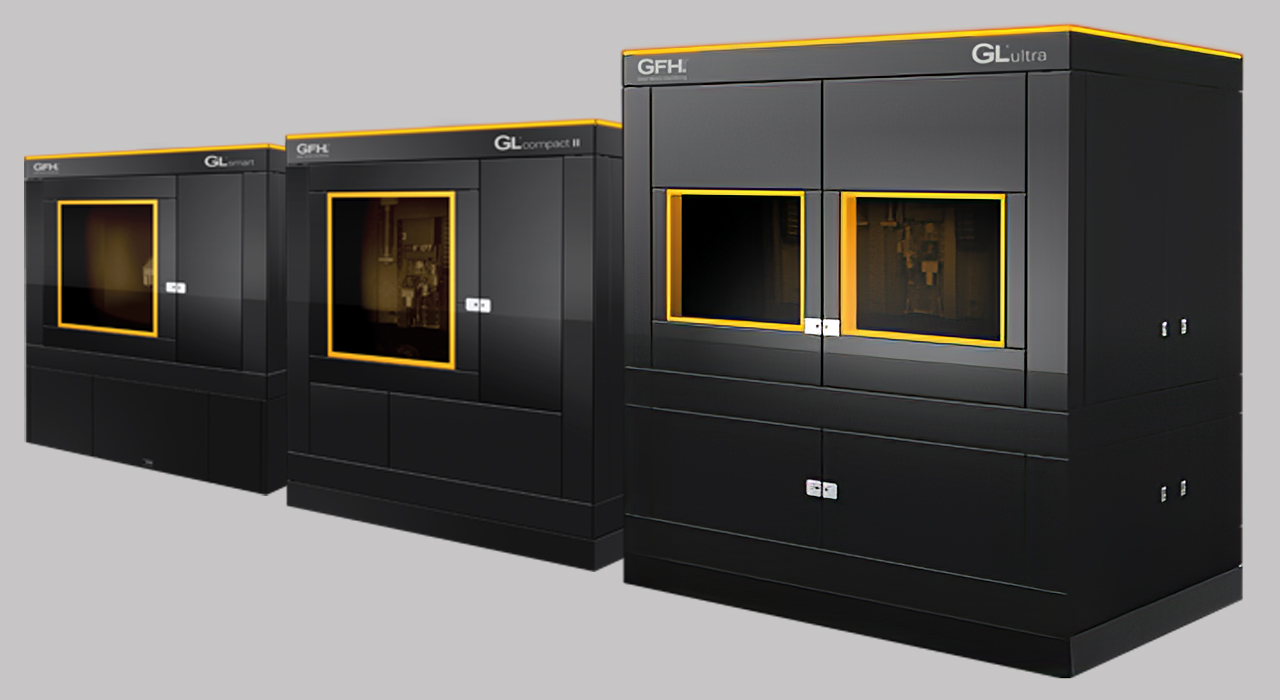

We build high precision laser micromachining systems with ultrashort pulse lasers in series. Our modular machine concept enables ideal equipment for your application.

PRECISION PRODUCTION

Professional support from process development to the finished component. Our laser systems as well as the process knowledge from more than 20 years of laser micro processing are at your disposal for this.

PROCESSES

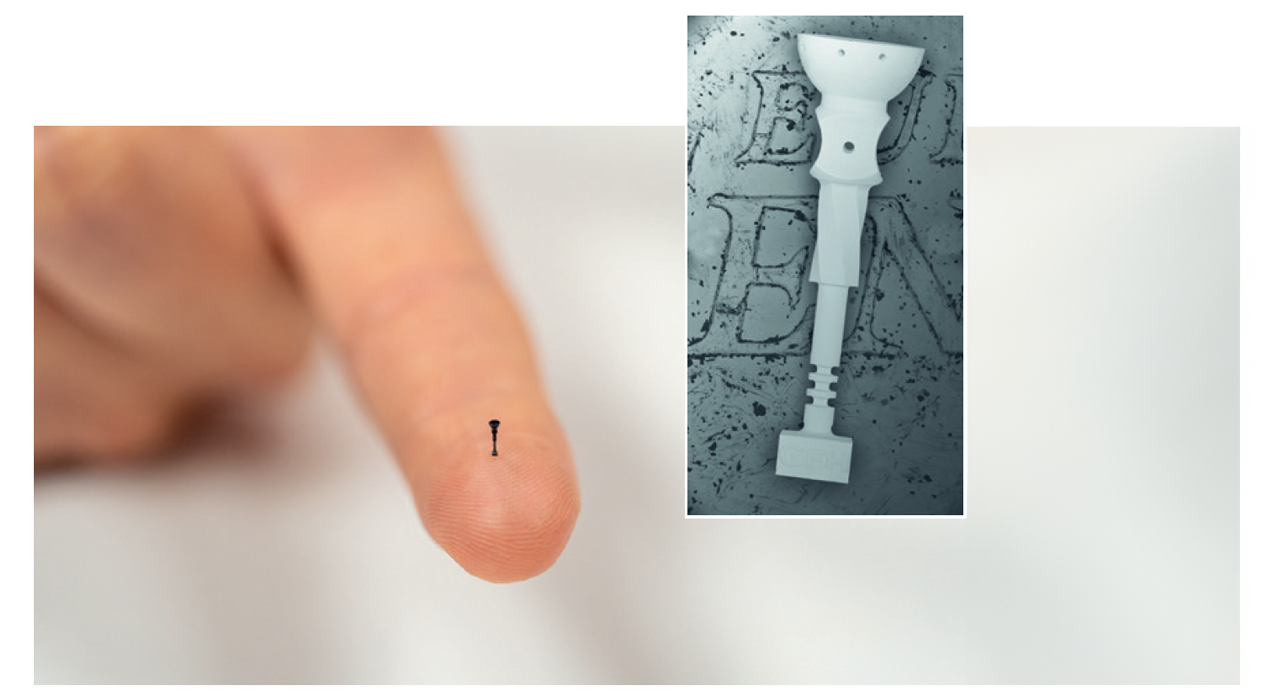

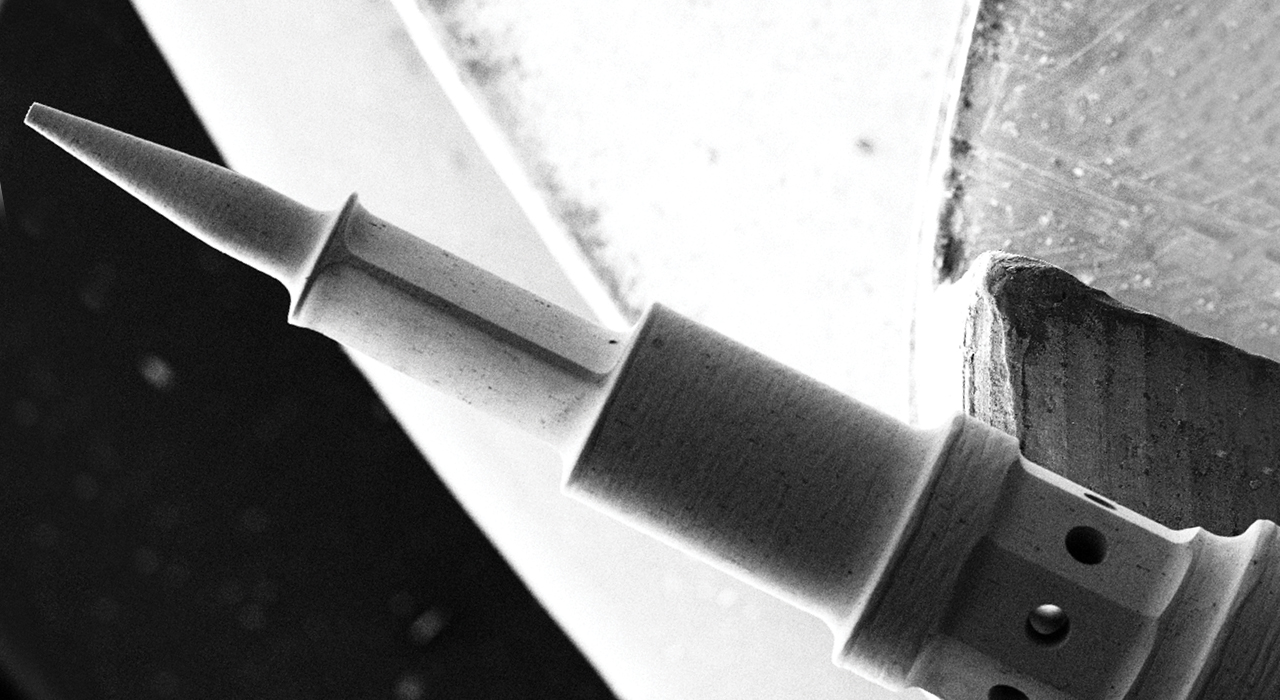

The ultrashort pulse laser is a flexible tool for high precision micromachining and is used by us for drilling, cutting, turning and engraving.

TECHNOLOGY

Ultra-short laser pulses vaporize any material and open up a new dimension of precision and quality in material processing.

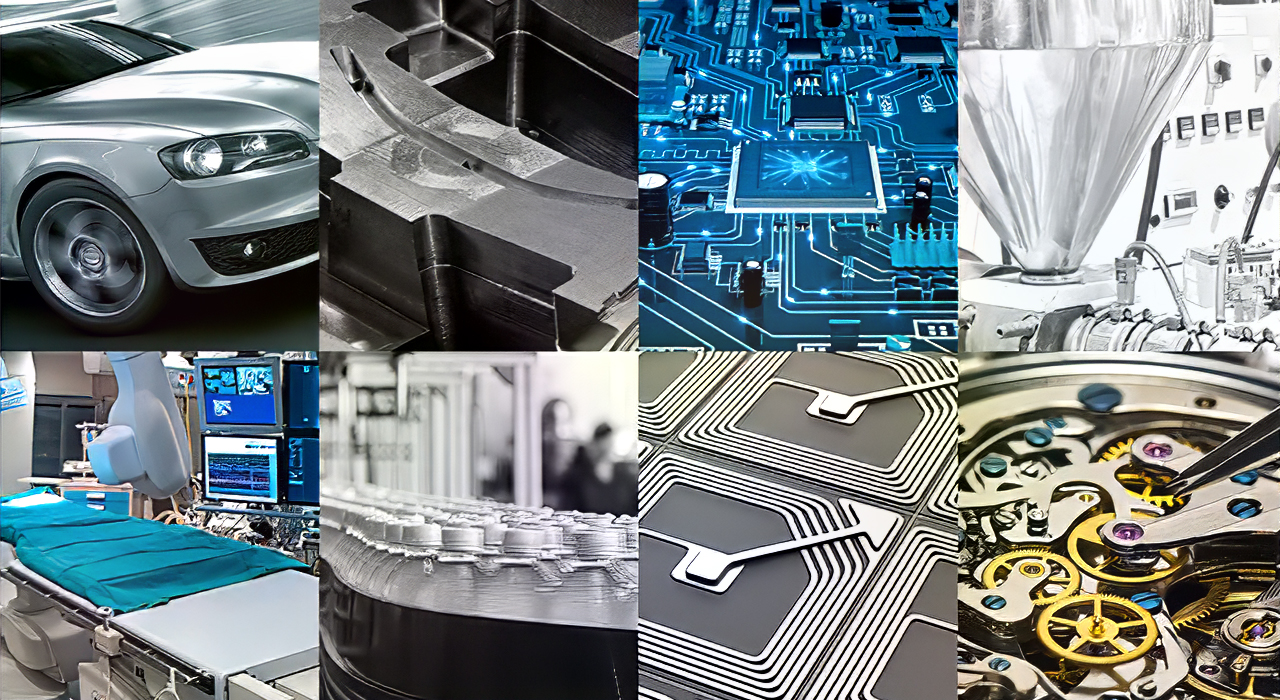

INDUSTRIES

Progressive miniaturization, increasing quality requirements and the use of new high-tech materials make the ultrashort pulse laser an indispensable tool in almost every industry.

COMPANY

More than twenty years of experience and unbridled innovative power make us a globally successful technology leader in laser micro machining.