Laser turning

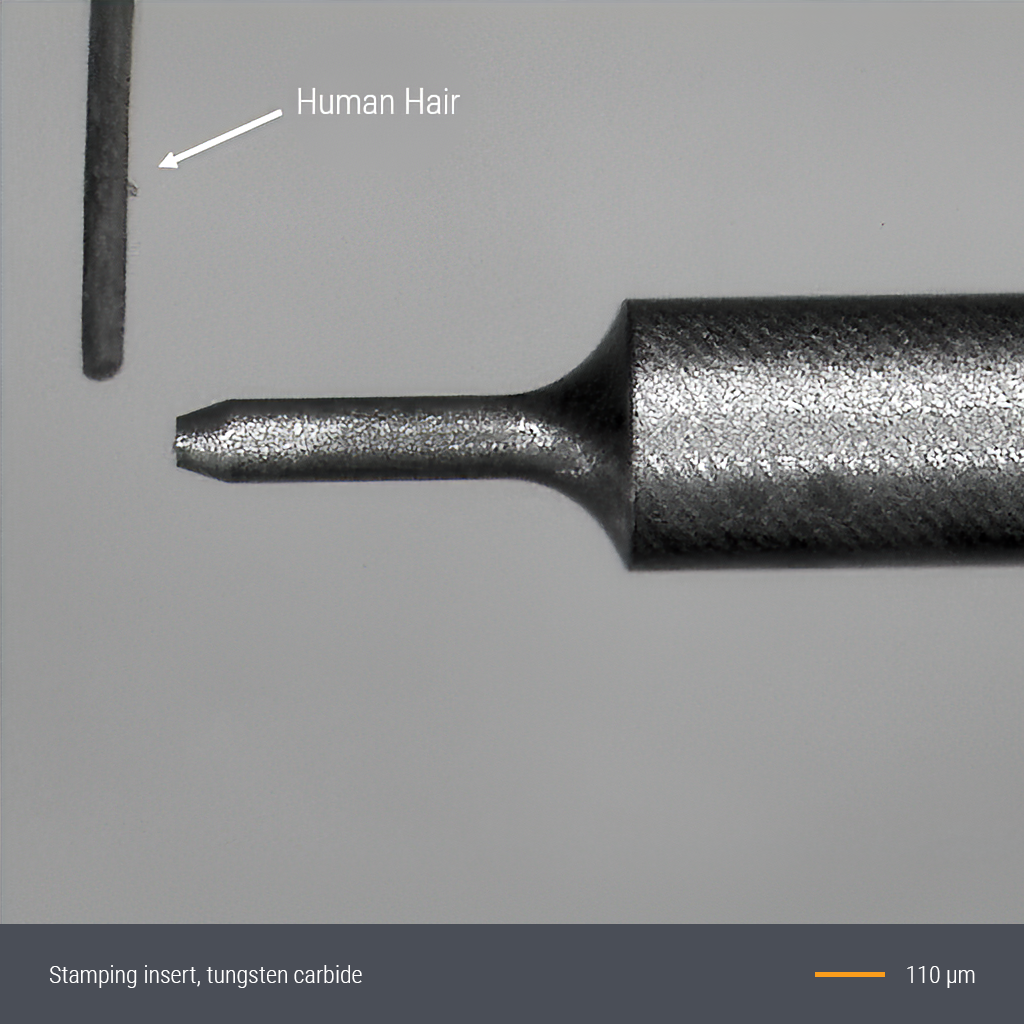

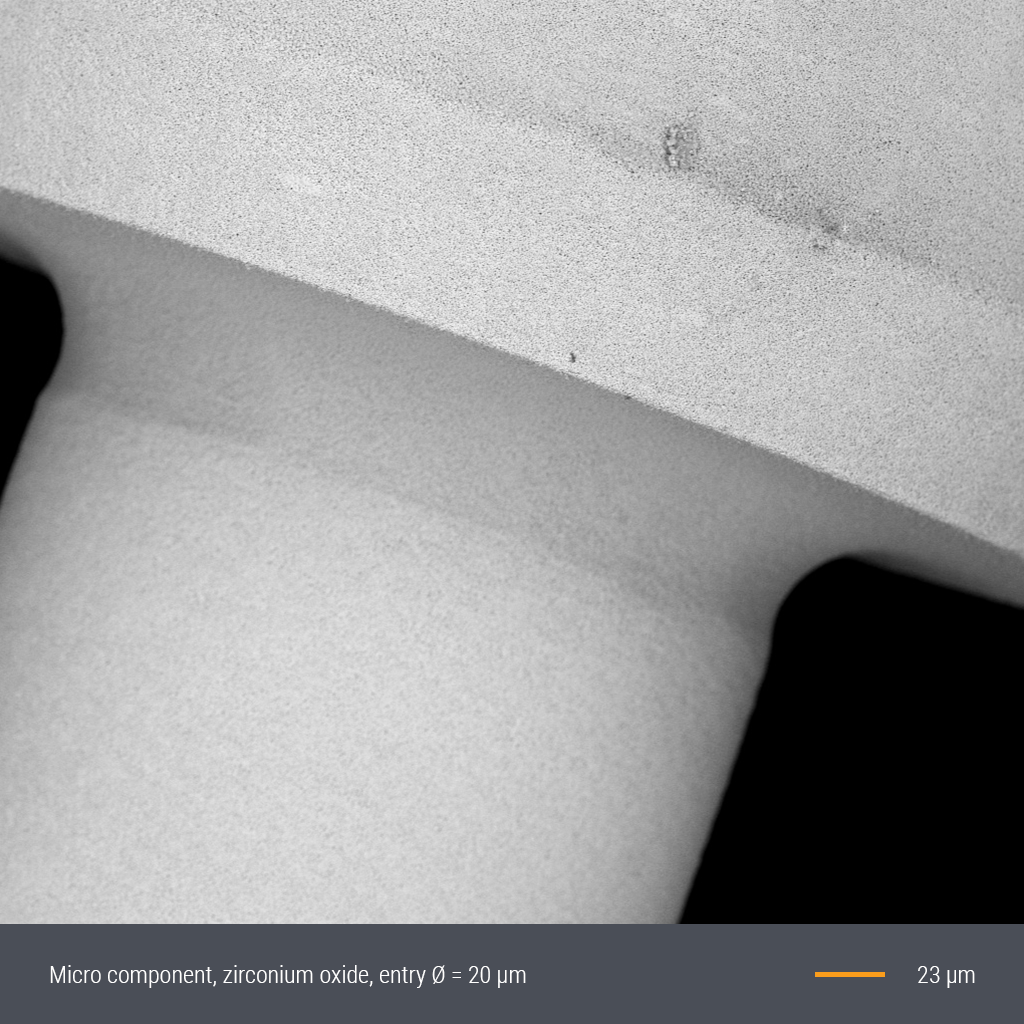

With laser turning it is possible to produce turned parts with the smallest diameters and any material. At the heart of the process is the combination of precise laser removal and a rotary axis with high-precision concentricity.

Thanks to the contactless removal mechanism, the workpiece remains free of forces and deformation throughout the entire time. Thus, even with very thin components, there is no loss of accuracy and even parts with a long clamping length can be machined by this way. The coupling of individual laser pulses to the workpiece position also makes it possible to adapt the heat input into the material to the respective workpiece volume, so that excessive heating and thus the occurrence of thermal stresses and deformations can be prevented. In addition, the surface characteristics that can be achieved in planar laser machining are completely maintained or even lowered with this machining variant.

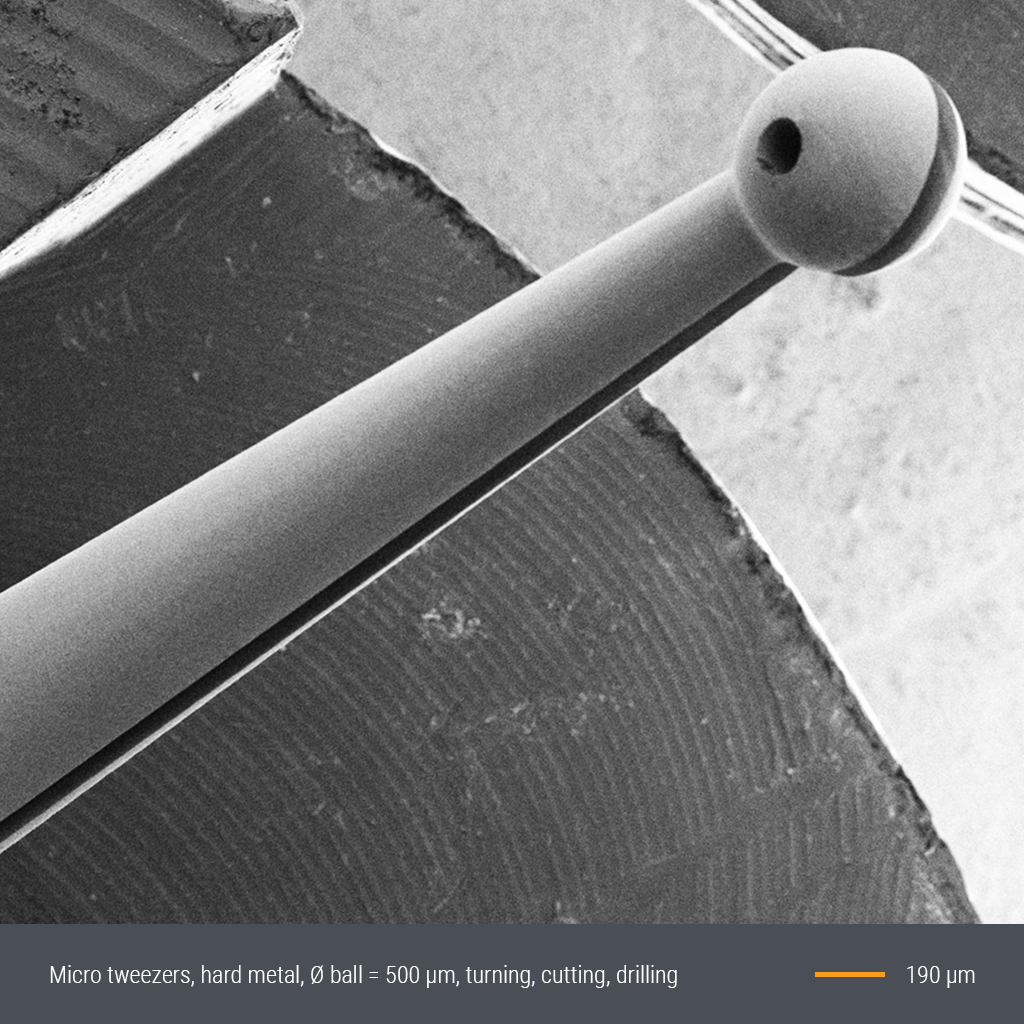

The machining in the five-axis machine allows turning to be embedded in a complete laser process chain. This allows the workpiece to be engraved, cut, drilled or structured before or after preparation without the need for additional clamping.