Micro drilling

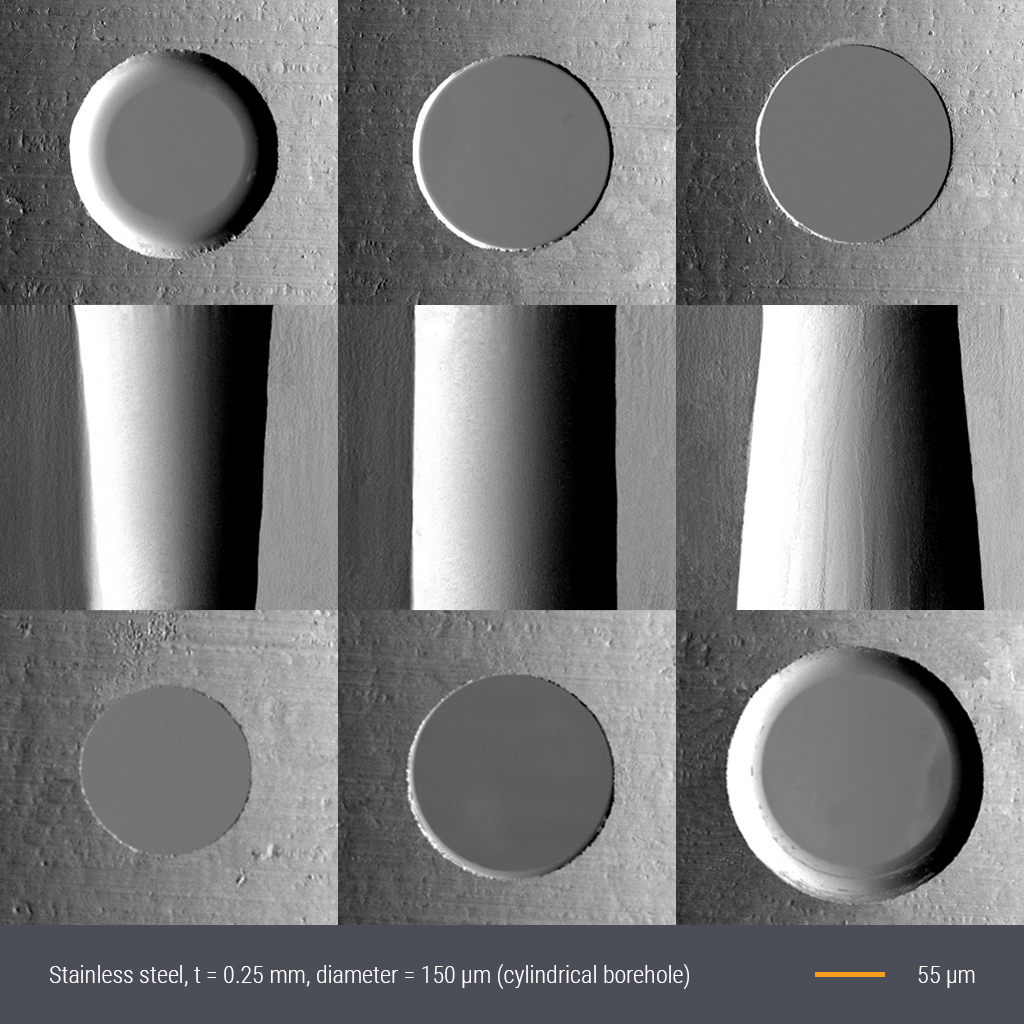

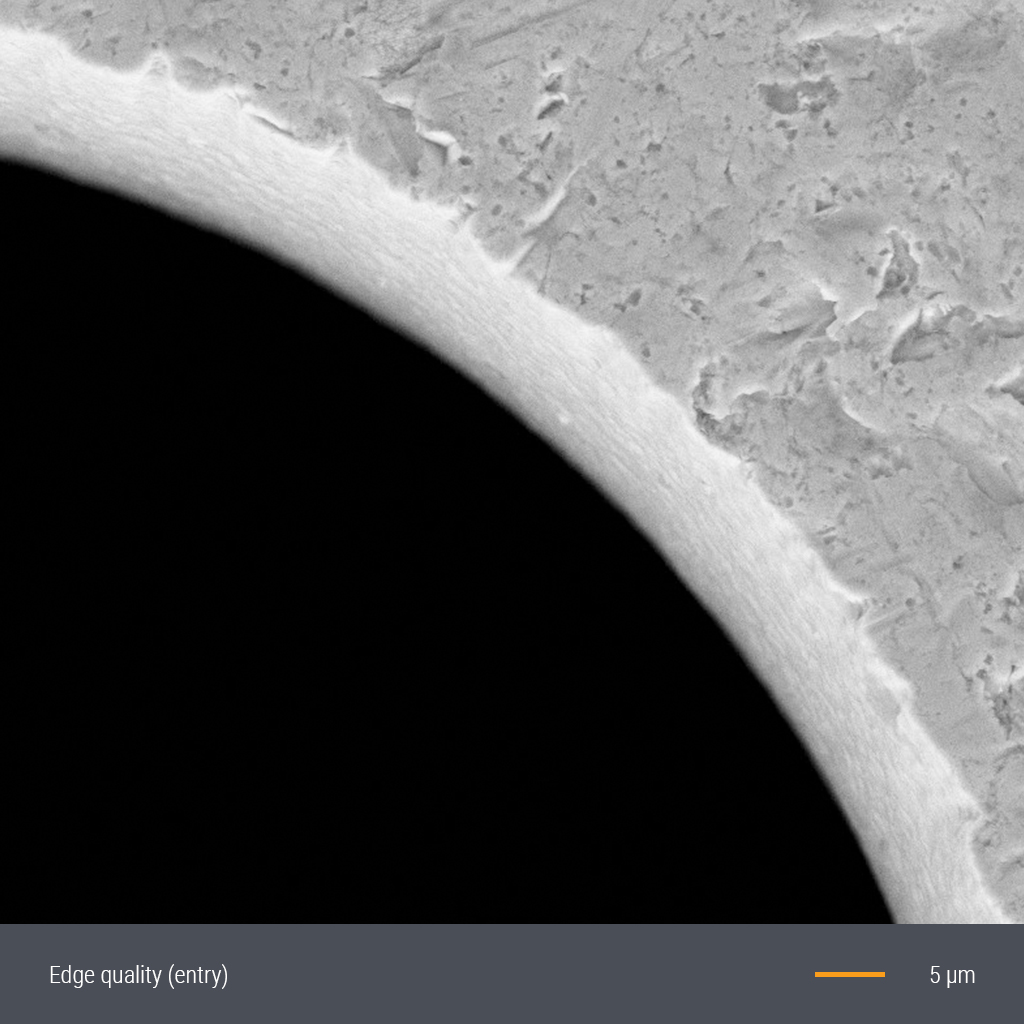

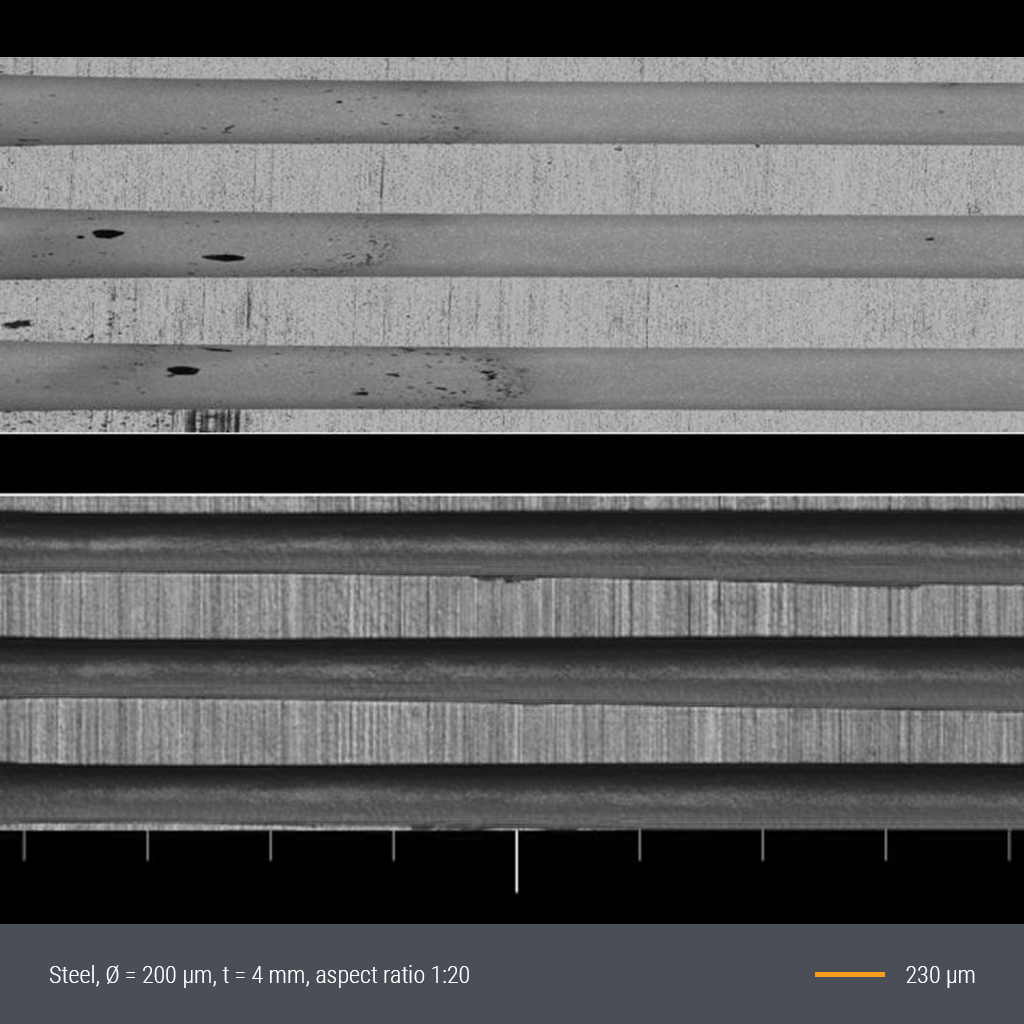

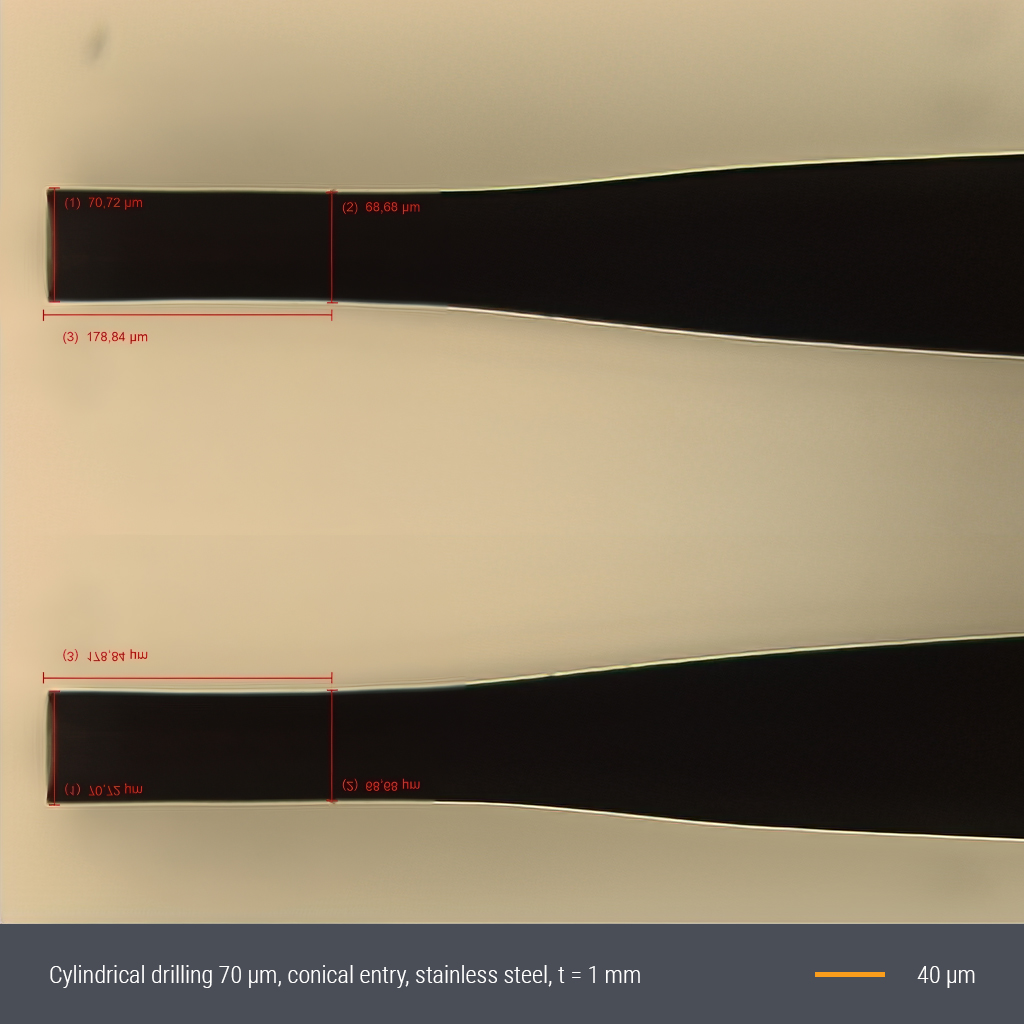

With the laser, a very flexible tool is available for the micro drilling process. Hole shapes can be realized from circular to elliptical and polygon to free forms. The cone of a borehole can also be specifically influenced. Depending on the future area of application, the borehole may be cylindrical in depth or may expand or narrow in a conical manner. Since the diameter can be generated by a rotational movement of the laser beam, it is possible to adjust it continuously to the desired size via a software setting. In addition, no rework is necessary due to the subsequent melting-free drilling process.

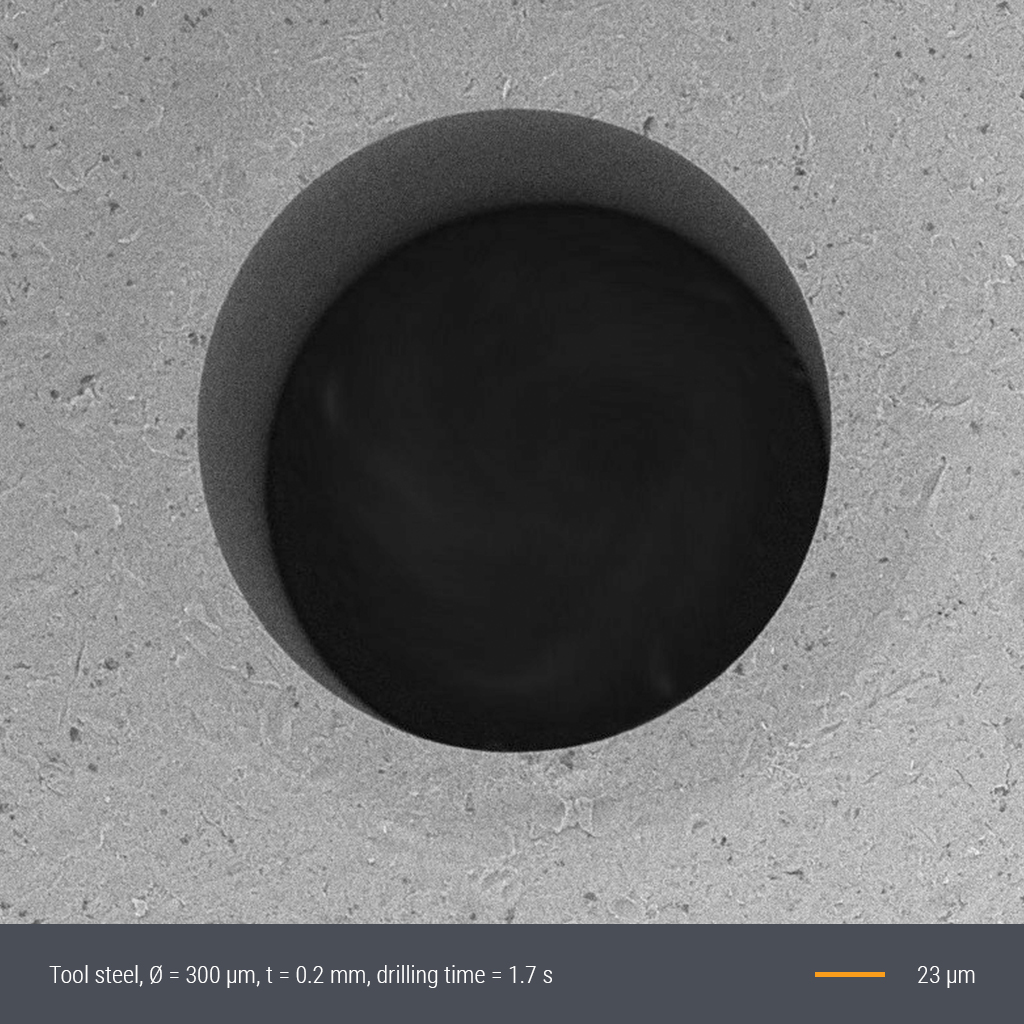

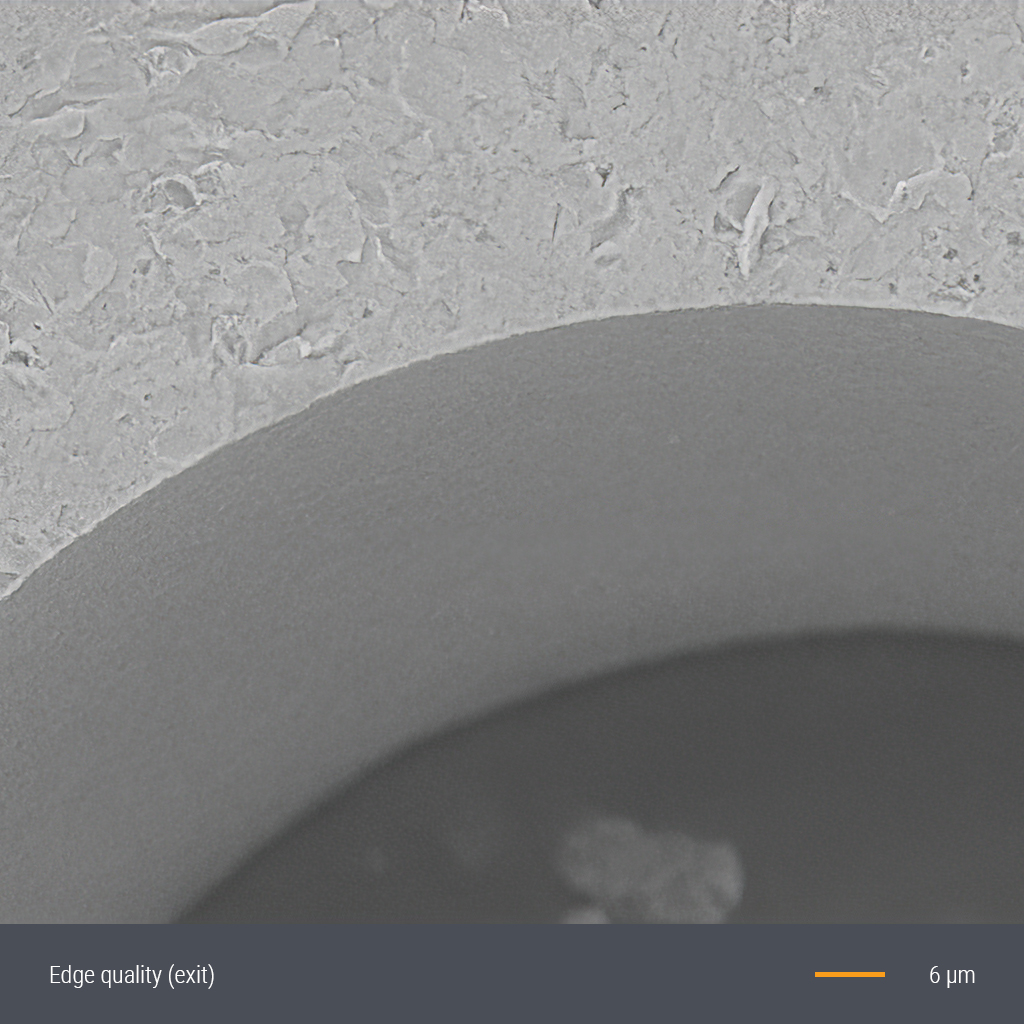

The applications are diverse. This is way the laser can create very small and precise holes with aspect ratios of up to 15. On the other hand, thin sheet metal, foils and layers are drilled almost burr-free at very high speeds in order to produce thousands of holes per minute, for example for perforations. Depending on the application and customer requirements, we suggest, select and optimize processes.