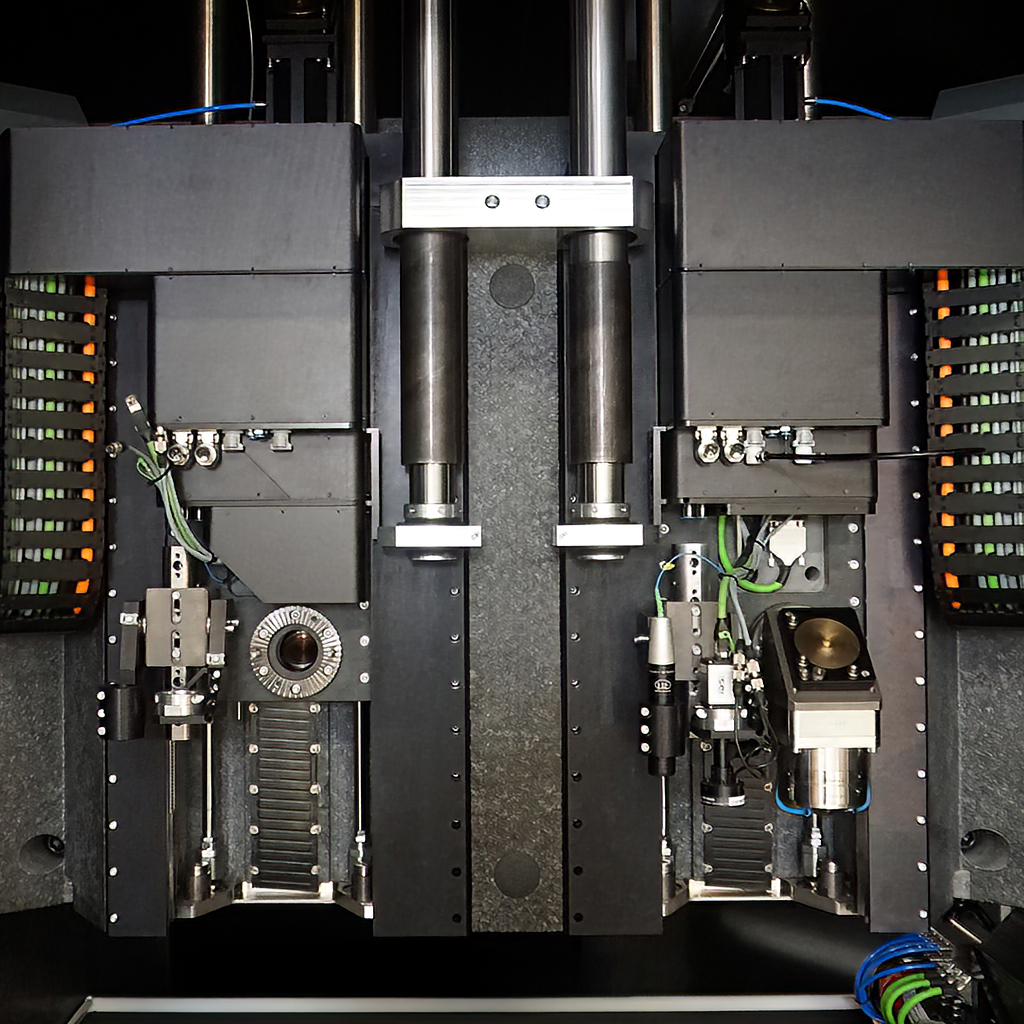

GL.ultra laser machine

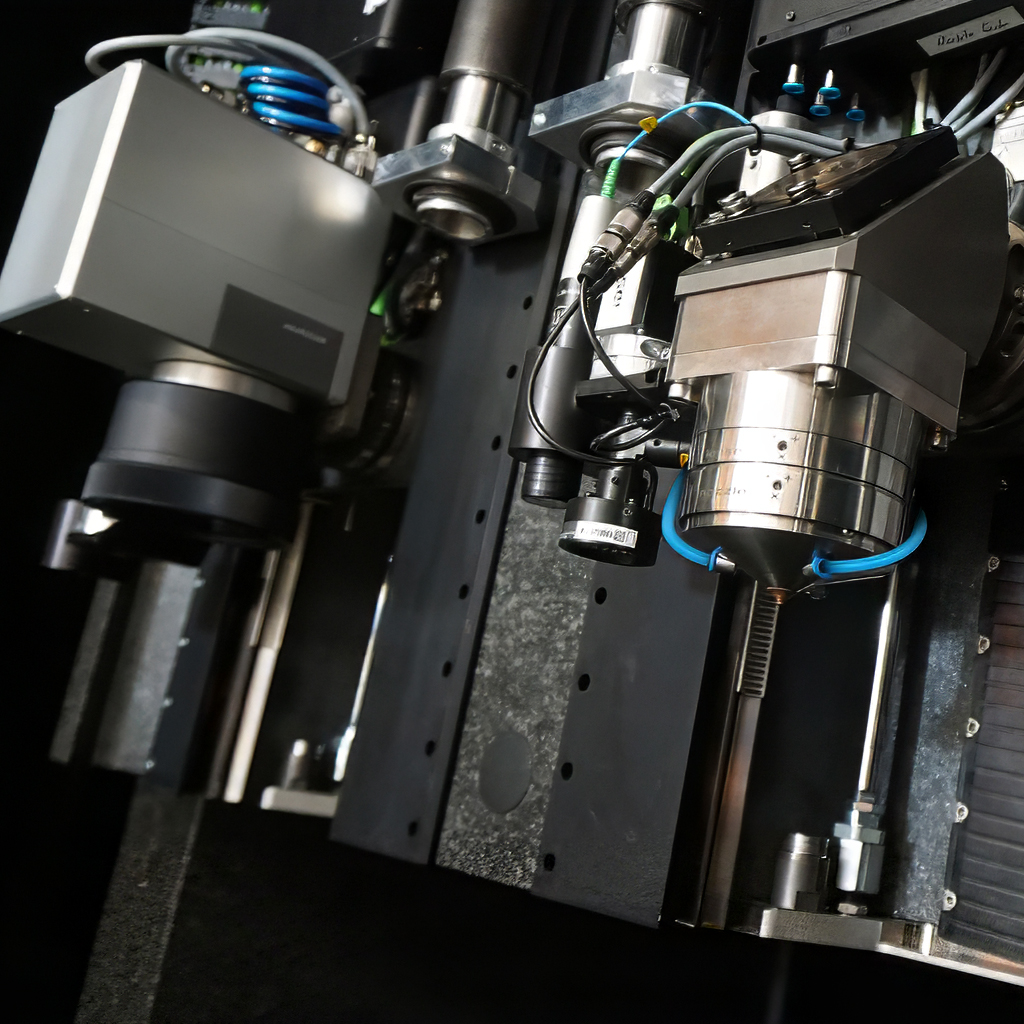

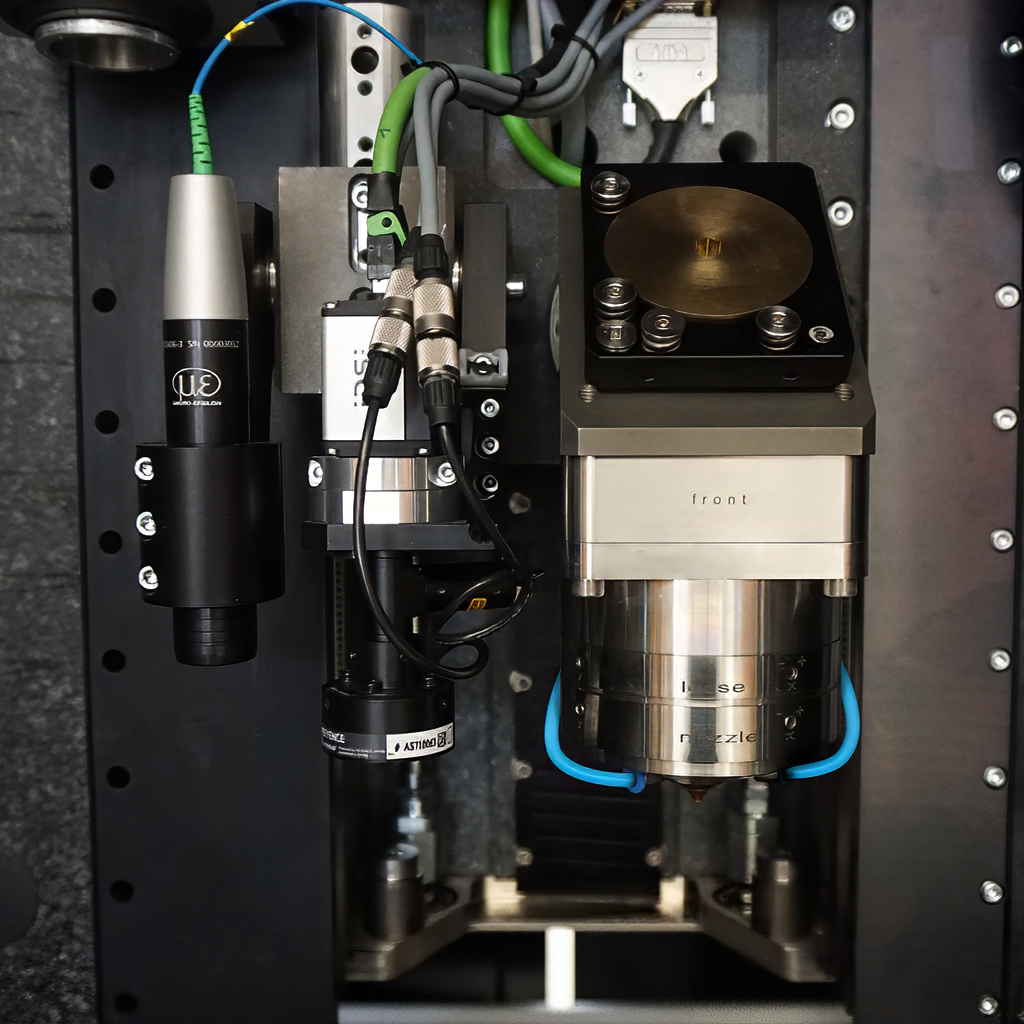

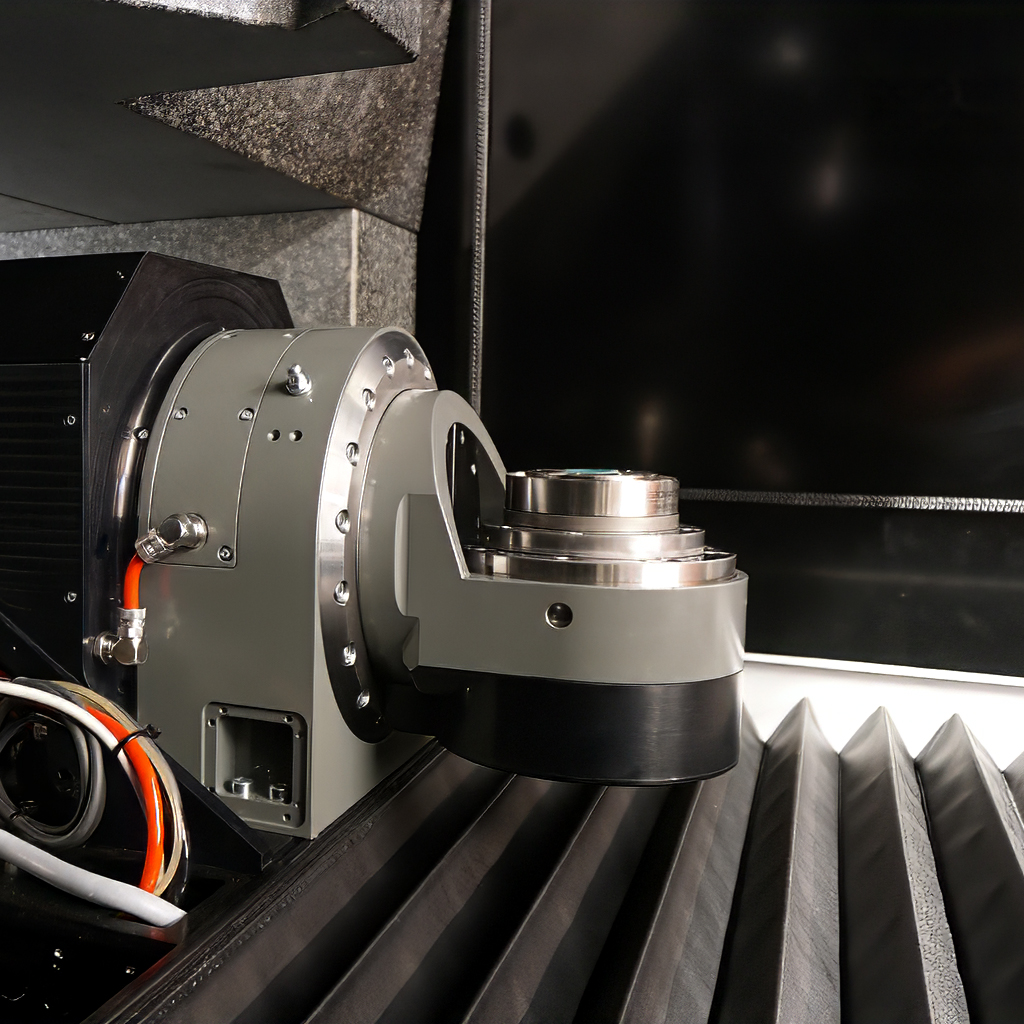

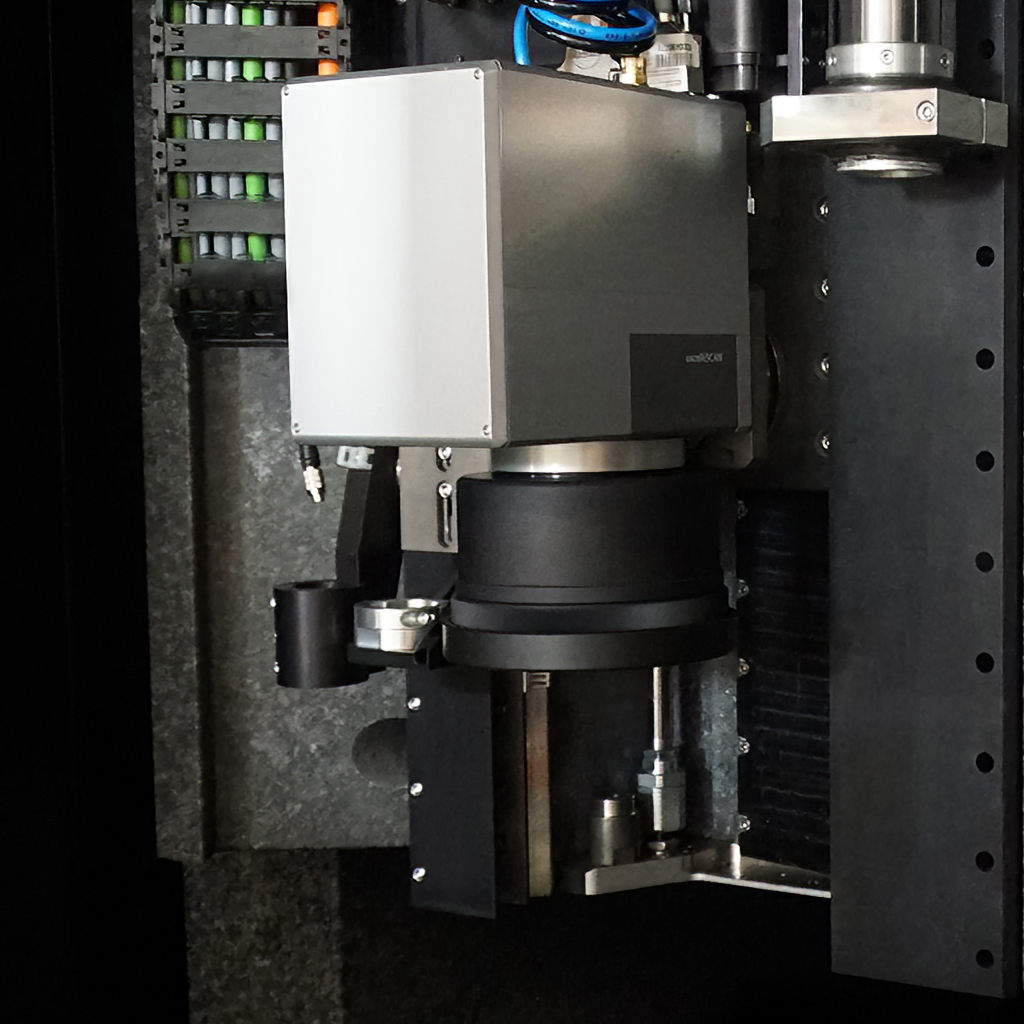

The GL.ultra as the largest laser machine of the GL. series offers a wide range of laser processing options with automated solutions, maximum laser on-time and therefore highest output with short cycle time. The integration of two 5-axis machining stations in one machine, as well as the possibility of integrating several laser systems in parallel, guarantee customers maximum investment security. A large number of interchangeable modules round off the new machine concept. On this occasion, the established advantages of “Hirth gearing” are consistently relied on in order to keep the changeover times as short as possible. In the course of the optional module selection, for example fixed or scanner optics can be installed that are compatible with all commercially available UKP laser sources. The patented axle kinematics in combination with two specially developed rotary and swivel units (X/Y-movable) offer maximum machining flexibility. The active water cooling of the drive and guide components and the granite slide guarantees the highest possible temperature stability. The innovative technology of GL.ultra is rounded off by the optical highlight of a sealed, black glass enclosure.

HIGHLIGHTS

PRODUCT IMAGES

TECHNICAL DETAILS

| Axis | X/P | Y/Q | Z/R | B/V | C/W |

|---|---|---|---|---|---|

| Axis type | linear | rotary | |||

| Drive type | direct drive | torque drive | |||

| Bearing | profiled rail guide | M&V-guidance | radial thrust bearings | roller bearing | |

| Travels [mm] | 1280 | 180 | 450 | +/- 110° | endless |

| Speed | 30 m/min | 280 1/min | 500 1/min | ||

| Acceleration | 5 m/s² | 160 1/s² | 220 1/s² | ||

| Repeatability | 1 µm | 2 arcsec | |||

| Positioning accuracy | 1,5 µm | 2 µm | 5 arcsec | ||

| Perm. comp. weight | 20 kg | 2 kg | |||

| Clamping set-up | clamping system | ||||

| Sound pressure level | ≤ 70 dB | ||||

| Dimensions [mm] | D = 2275 / W = 2275 / H=2625 – without supply unit | ||||

| Component flat | X/P: 350 Y/Q: 250 Z/R: 300 | ||||

| Component round | Cylinder with diameter 120 mm and height 185 mm on all sides, down to the floor surface, minus clamping system | ||||

| Total weight | 14 t without supply unit | ||||

HARDWARE MODULES

All GL.smart modules.