GL.smart laser machine

The compactly constructed laser machine offers besides the possibility of combined machining of laser drilling, turning, and cutting, an increase in output for the customer by parallel machining on two stations. The integration of a bar loader as a loading unit and the removal of the finished parts by a six-axis robot ensures complete autonomy of the laser drilling machine.

All heat sources in the laser drilling machine, including the direct drives of all axis will be actively cooled with water. The machine concept of GL.smart is aimed at machining rotationally symmetrical components and also offers the option of 3+2 axis machining with the optional counter spindle.

The deep integration of our components into the control system enables online monitoring of production processes as well as efficient service and therefore fulfils all requirements of a production machine.

HIGHLIGHTS

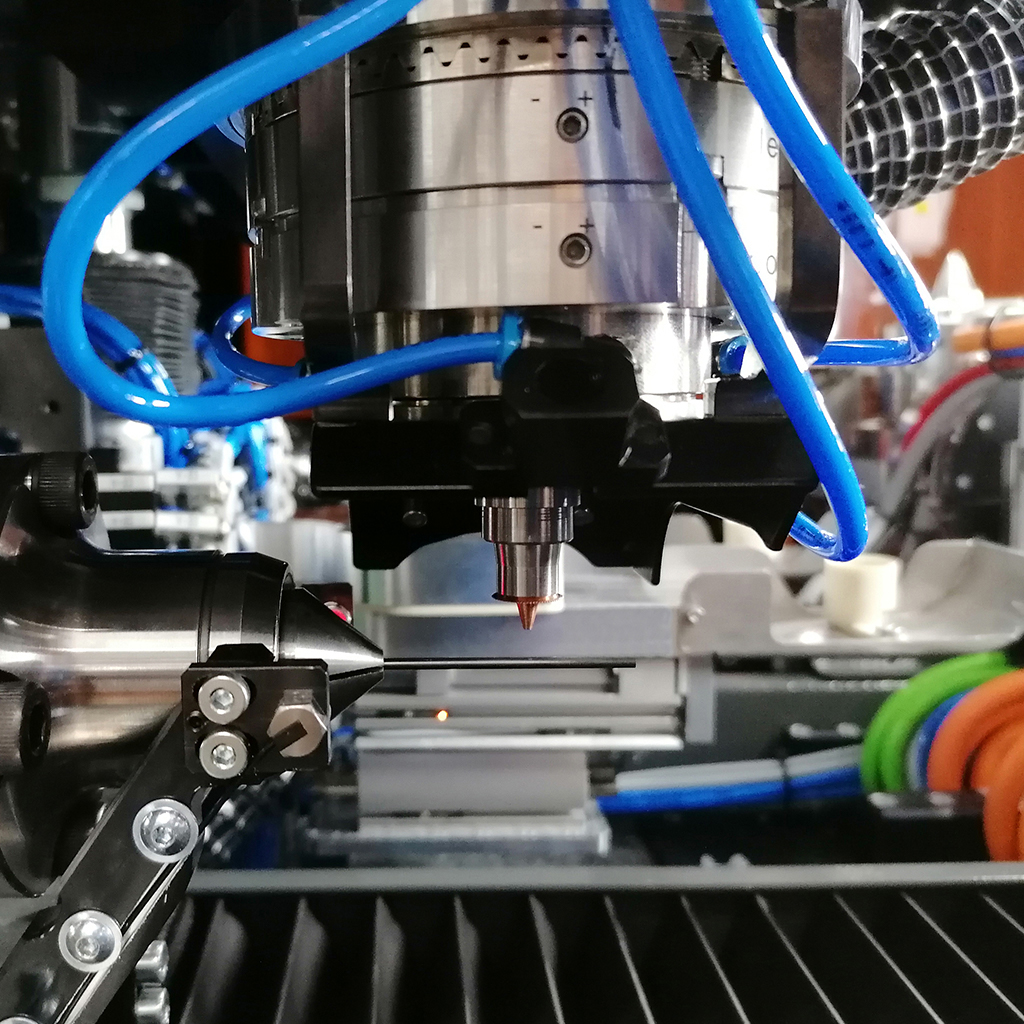

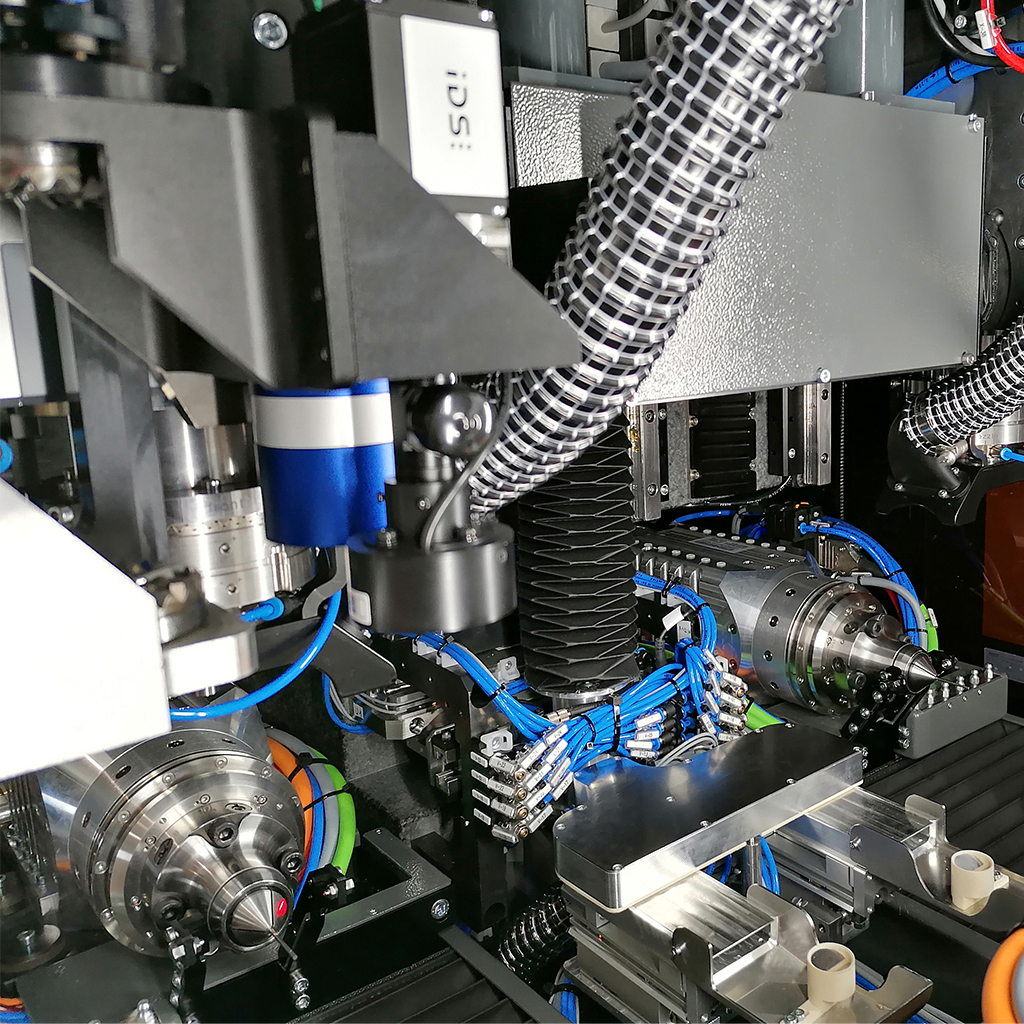

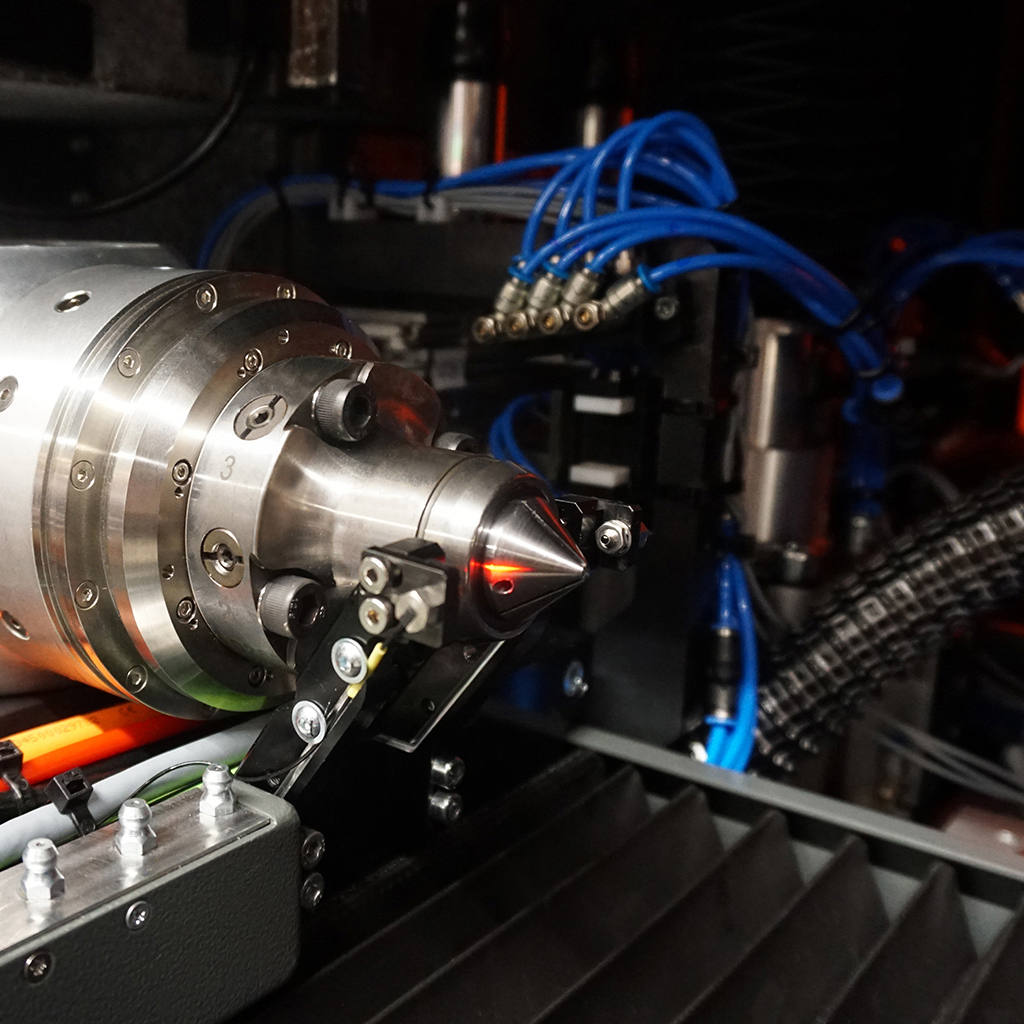

PRODUCT IMAGES

TECHNICAL DETAILS

| Axis | X/P | Y/Q | Z | A/U | B/V | C/W [GL .rotil SE] | C/W [GL .rotil SE air] |

|---|---|---|---|---|---|---|---|

| Axis type | linear | rotary | |||||

| Drive type | direct drive | torque drive | |||||

| Bearing | profiled rail guide | M&V-guidance | profiled rail guide | air bearings | roller bearing | air bearings | |

| Travels [mm] | 500 | 40 | 220 | endless | +/- 90° | endless | |

| Speed | 30 m/min | 3500 U/min | 700 U/min | 700 U/min | 2500 U/min | ||

| Acceleration | 5 m/s² | 150 1/s² | 160 1/s² | 220 1/s² | – | ||

| Repeatability | 1 µm | 2 arcsec | 10 arcsec | 2,5 arcsec | |||

| Positioning accuracy | 2 µm | 3 arcsec | 20 arcsec | 5 arcsec | |||

| Perm. comp. weight | customized component testing | 0,5 kg | |||||

| Clamping set-up | drilling pattern | clamping system for collets | clamping system | ||||

| Sound pressure level | ≤ 70 dB | ||||||

| Dimensions [mm] | D = 1026 / W=2212 – Height depends on laser – H = 2333 or H=2483 – without supply unit | ||||||

| Rod bearings | On request | ||||||

| Parts magazine | In accordance with customer component | ||||||

| Total weight | 3700 kg without suplly units | ||||||

HARDWARE MODULES

All GL.smart modules.