Engraving

We differentiate between two engraving processes, deep engraving and microstructuring:

DEEP ENGRAVING

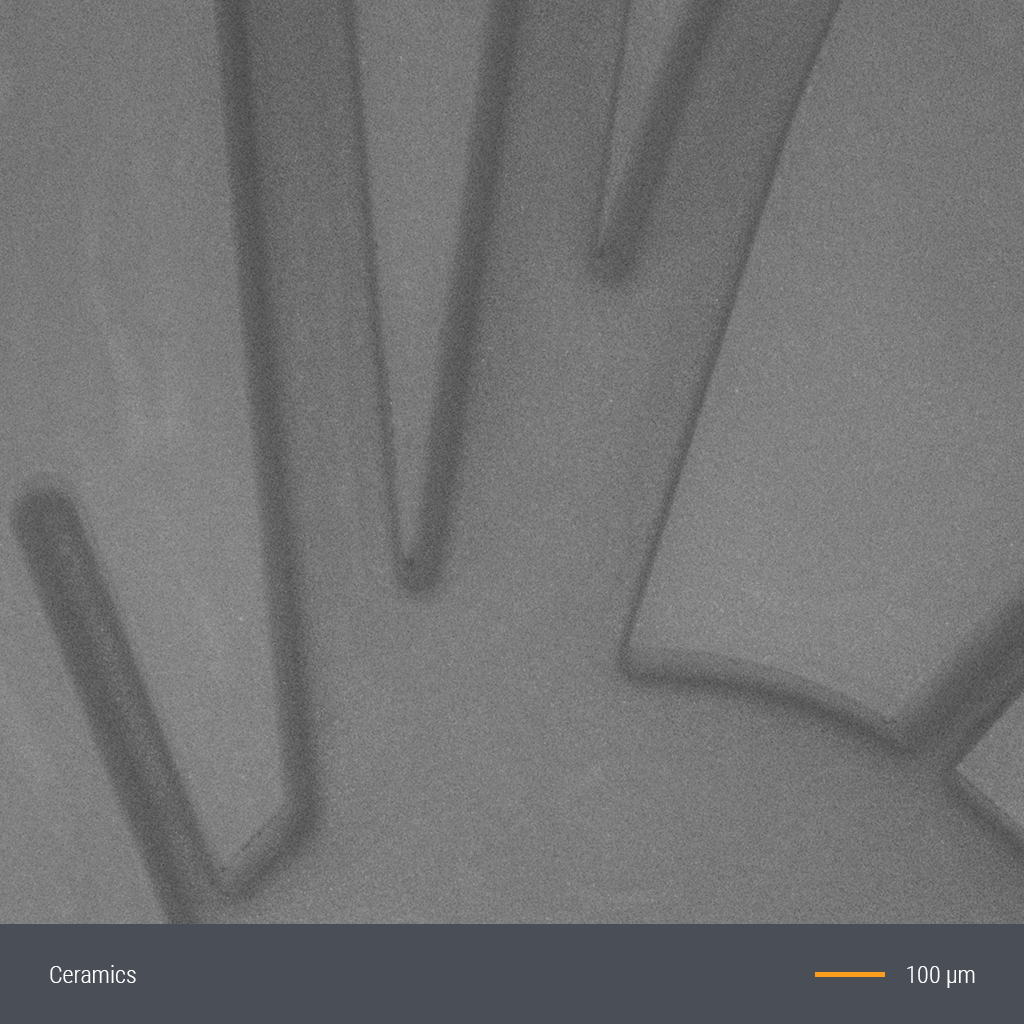

With deep engraving, volume is removed with the laser, creating a new shape for the workpiece. The laser as a tool allows to transfer a 3D volume directly from a CAD model to a workpiece.

For this purpose, the volume is transformed into a layer model and the material is removed from the workpiece surface along the generated layers with the laser. In this way, a negative form of the original model is gradually created. Removal is possible on flat components as well as on cylindrical, spherical or conical surfaces.

The basic advantages of laser processing are retained in this process. With deep engraving, the edges remain burr-free and the roughness of the surface in the processing zone is in the range of mechanically lapped surfaces.

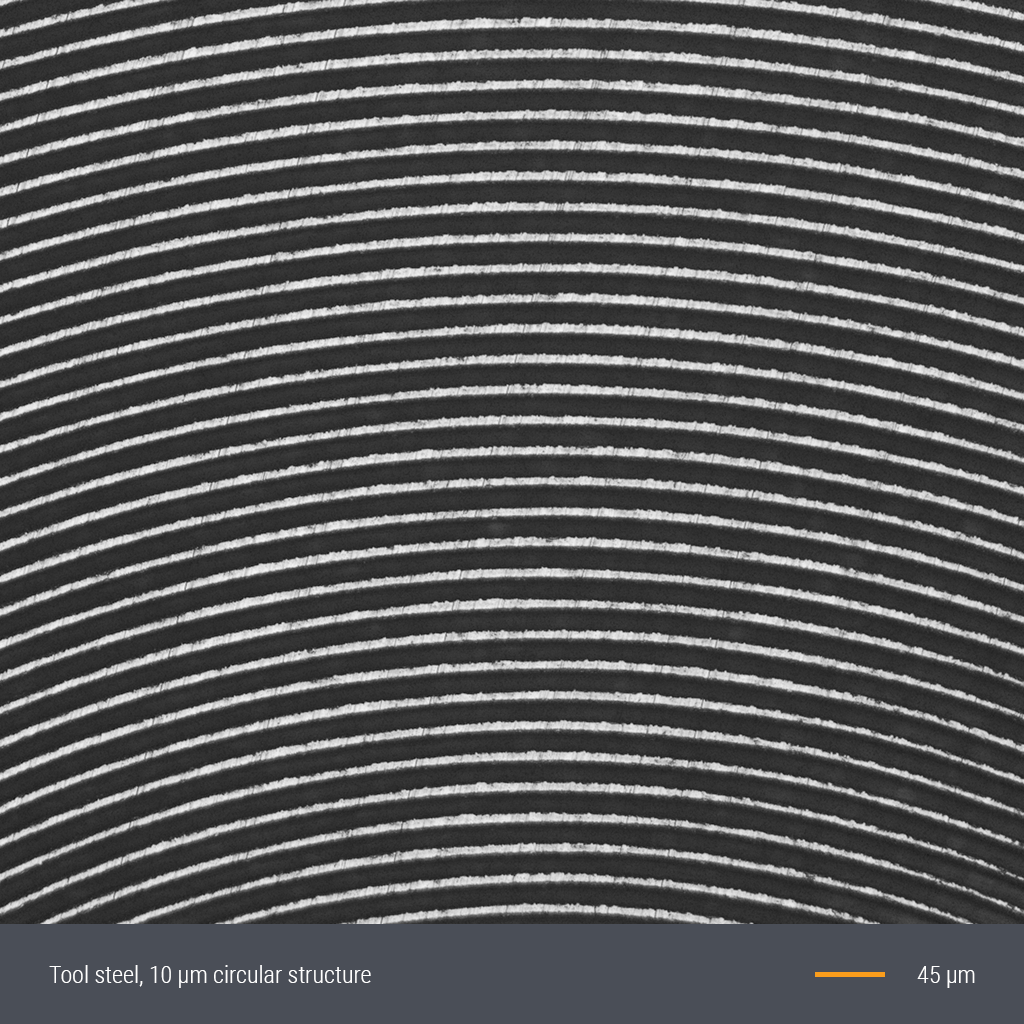

MICRO STRUCTURING

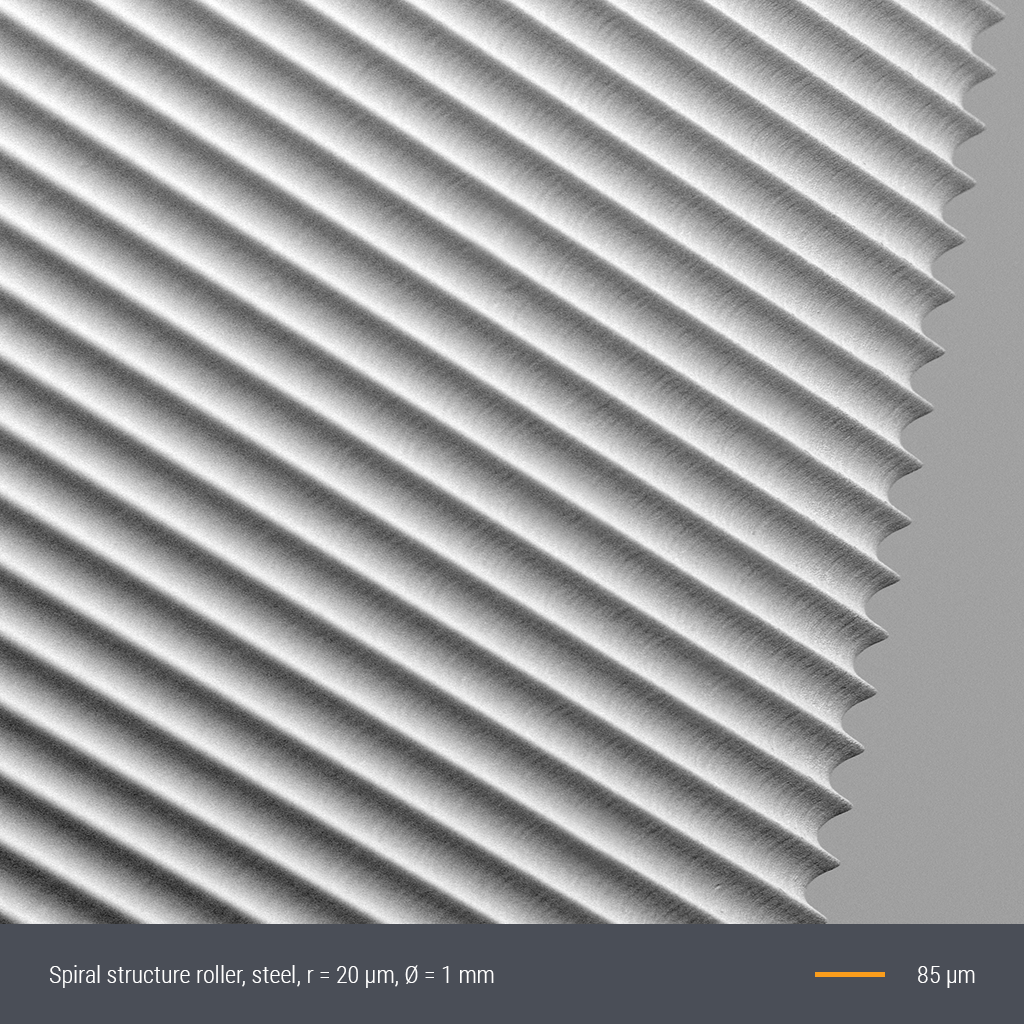

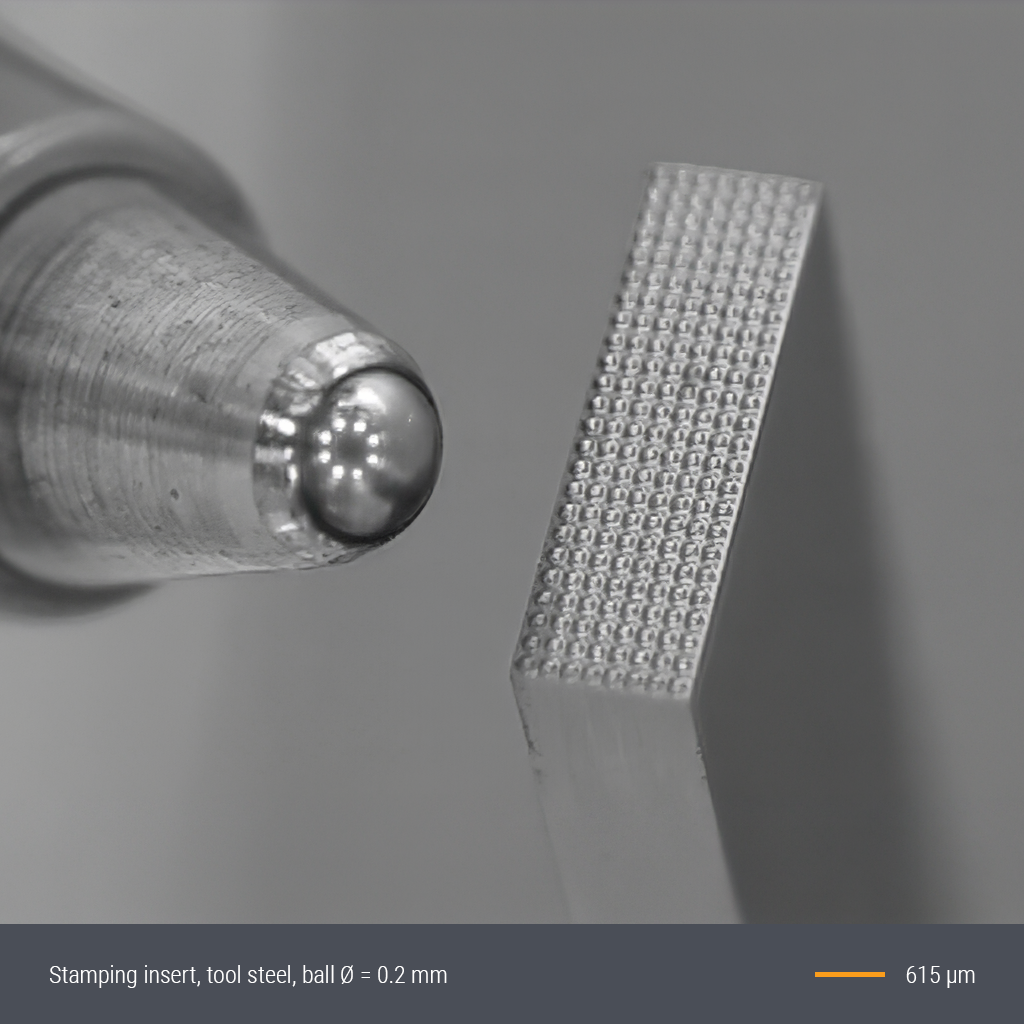

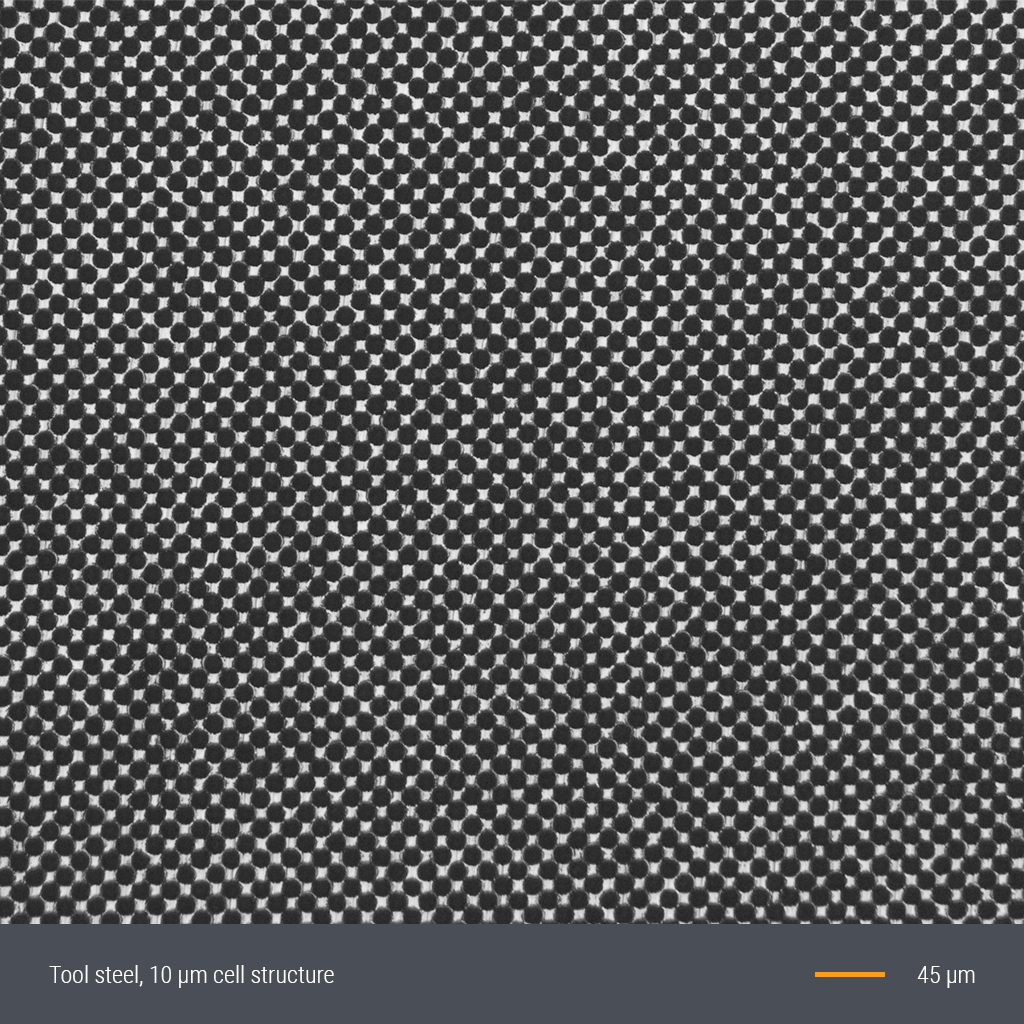

In addition, the laser allows the surfaces of workpieces to be specifically influenced by the insertion of microstructures. This includes the adjustment of the desired surface roughness, but also the application of tribological structures and the change of wetting ability.

Microstructuring can be used as its own machining process but also as a final finishing after other processes such as laser cutting or engraving.