Interview with Florian Lendner – “In Search of the Last Micrometer” – GFH GmbH

Wirtschaftsforum: Mr. Lendner, what events have been particularly significant in the history of GFH?

Florian Lendner: GFH was founded in 1998 by Prof. Dr. Hans Joachim Helml, who is still the main shareholder. Initially, the company focused on research and development in laser manufacturing in the field of injection technology. The company, initially closely linked to the university, moved to its own building in 2004. In 2005, a prototype was completed for a client, enabling the drilling of diesel injection nozzles with lasers. We used the experience gained from this to develop our own machine, with a special focus on precision. Since 2008, we have been on the market with a series solution.

Wirtschaftsforum: Were you active in specific industries back then?

Florian Lendner: In the early years, we served all major clients in the field of injection technology with small series and feasibility studies. Then, we shifted our focus to manufacturing components for mechanical precision watches. In 2012, we downsized the first model of our machine for the watch industry. In 2012, a part of the company was sold, and the funds were reinvested in establishing precision manufacturing with ultra-short pulse lasers. Today, alongside machine manufacturing, we also offer contract manufacturing from prototypes to series production in the high six-figure range. In 2016, we began developing a new generation of machines.

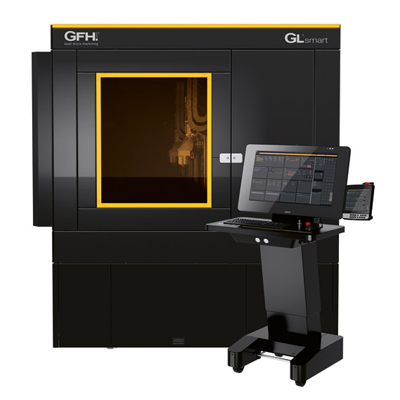

The new developed laser machine GL.smart with up to 16 simultane axis is the all-purpose weapon in the laser micro machining sector.

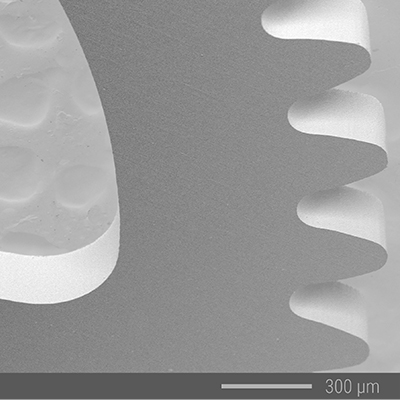

Gear: Precision cuts for precision parts - GFH machines are used to manufacture various parts of mechanical watches, such as gears.

Trophy cup: A sample part showcases the full flexibility of ultra-short pulse laser processes - drilling, cutting, ablation, and turning - all in just one setup.

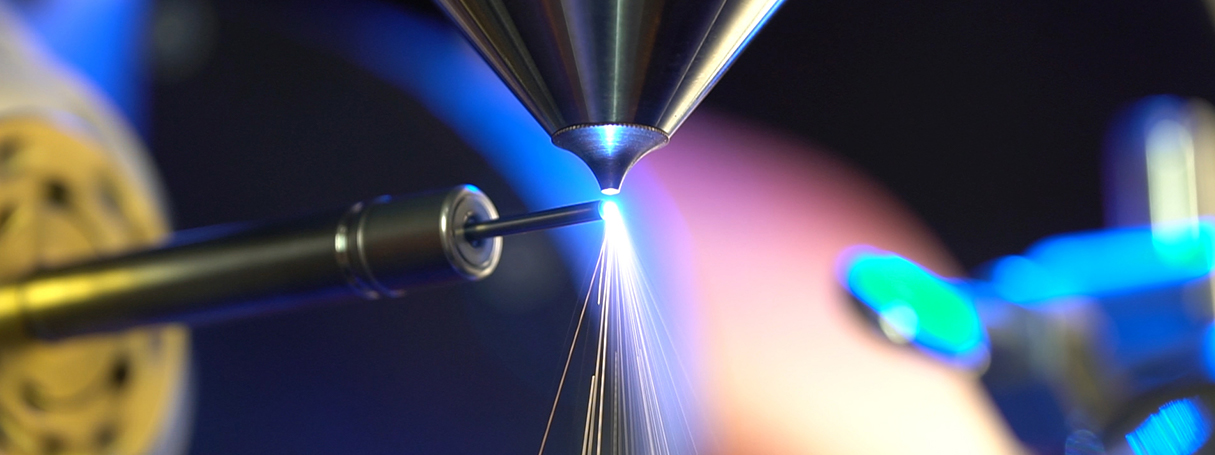

Wirtschaftsforum: What is special about the lasers you use?

Florian Lendner: These ultra-short pulse lasers allow for even higher precision in the micrometer range, as they do not generate heat in the material. The second advantage is that they can process any material. We offer four laser processes: laser drilling, laser cutting, ablation or engraving, and laser turning.

Wirtschaftsforum: Can you provide examples of areas where your products are applied?

Florian Lendner: In medical technology, for example, implants, minimally invasive surgical instruments, or leakage holes in small glass vials for quality control evaluation are manufactured. In the luxury segment of the Swiss.

Precision watches: Our machines are used for high-quality engravings or for manufacturing precision parts of the watch movements. For example, through our laser turning process, ceramic bearing shafts are produced, which cannot be manufactured with conventional methods with this precision, thus further increasing the accuracy of the watches. Our customers produce components with highly precise bores for the semiconductor industry, which are needed for the chip production of the latest generation. They manufacture holders for the smallest measuring probes for metrology, structure shafts for wear-free gas bearings, or drill finest holes in the textile industry for tools used in the production of high-tech yarns. In addition, there are numerous other applications in various industries, such as the electrical and automotive industries or aerospace. Since these applications usually involve new product developments, these projects are generally subject to confidentiality.

Wirtschaftsforum: How do you differentiate yourself from your competitors?

Florian Lendner: With the ultra-short pulse laser, we operate in a niche area, and within this, we focus on high precision. Our motto is to search for the last micrometer. Additionally, we come from laser process development and have over 20 years of process experience, particularly in laser drilling. We support our customers in manufacturing components with the right quality, time, and excellence. In our precision manufacturing, we have experts with decades of experience operating the machines. We consider ourselves technology leaders in high-precision drilling and laser turning.

Wirtschaftsforum: What personally drives you in your work?

Florian Lendner: I am an engineer and have studied business administration. I have been with this company and this technology for many years. For me, my work here is extremely fascinating because we push boundaries every day. We come into play when conventional technologies reach their limits.