Laser intelligence that inspires

Whether it's the electronics, watchmaking, or tool industries, medical technology, aerospace, or the production of smartphones and tablets, the use of ultra-short pulse lasers offers unbeatable advantages in high-precision manufacturing. GFH GmbH from Deggendorf has developed corresponding equipment for laser micro-processing and has thus become one of the global market leaders. At GFH, intelligence isn't just in the minds, but soon also in the machines.

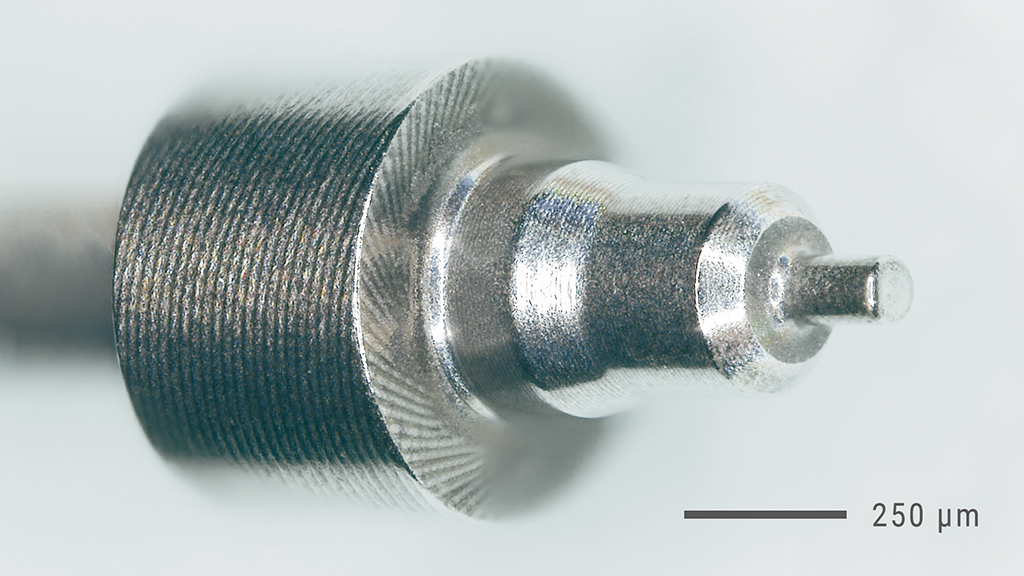

When Hans Joachim Helml founded the company 21 years ago, he and his team were occupied with the question: Can the erosion of diesel injection nozzles be replaced by laser processing? "This research project ran until 2005. Its goal was to build a machine that enables drilling with lasers of the same quality," Florian Lendner, who has been with the company since 2008 and has been its CEO since early 2019, recounts. He continues, "The laser machine was delivered, but drilling was not economical for serial production. However, we saw the potential of laser technology." Thus, GFH began developing its own types of machines: The GL.evo machine tool can be universally used for laser microprocessing in the high-precision sector. For the watch industry, a smaller variant, the GL.compact, was introduced to the market. Laser technology took further leaps. "The development of the ultra-short pulse laser, emitting pulses in the pico- to femtosecond range, has boosted the entire technology. It allows extremely delicate processing without mechanical intervention and is suitable for any material," Florian Lendner explains the advantages. This year, three more machine types with this technology for laser microprocessing were developed. GFH also fulfills special customer requests by building custom machines. The proprietary technology is also used for precision manufacturing of small batch sizes from prototype to series.

High-end for the middle class

In addition to a sales office for the watch industry in Switzerland, the company, which employs 85 people, is currently establishing another branch in China. "We are well positioned and expect disproportionate growth," says Florian Lendner. The starting position is excellent: GFH is not only capable of selling machines worldwide but also a technological pioneer and market leader in high-precision machining. Furthermore, the company is the only provider capable of offering laser turning, a process for the highly accurate machining of rotationally symmetric components, which enables drilling, cutting, and structuring in the same operation. "With newly developed products, we aim to contribute to the widespread adoption of the technology," emphasizes the CEO. A won EU research project plays an important role in this. "It's about how to make such technology accessible to small and medium-sized enterprises, and about how we can bring intelligence into the machines," explains Florian Lendner.

Technology with potential

As a technology-oriented company, it's clear how crucial the expertise of the employees is. Florian Lendner is convinced that the disproportionately growing ultra-short pulse industry offers GFH many opportunities: "We want to continue growing in various markets, in Germany and the EU, and enter new markets." His fascination for the technology remains unchanged. "The technology is incredibly exciting and has tremendous potential. For companies, regardless of their size, it's always a high-end technology," says Florian Lendner, who will "always remain an engineer at heart."