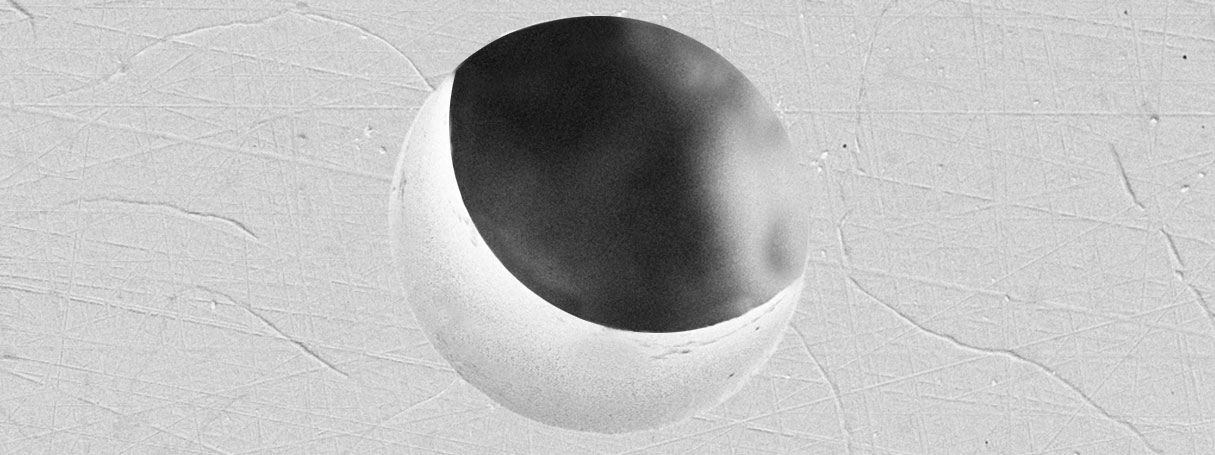

Laser drilling / micro drilling

Mass Production in the Automotive Industry

In addition to flexibility, efficiency, and cost-effectiveness, laser drilling methods open up entirely new possibilities in the processing of workpieces. For these reasons, innovative laser applications are gaining increasing importance in the automotive industry. GFH GmbH is one of the global technology leaders in the production of laser drilling systems. With this highly precise system technology, GFH GmbH offers the possibility of wear-free laser drilling for, among other things, injection nozzles, throttles, and diaphragms, oil supply holes, and ventilation holes. The applied laser drilling method has several advantages over conventional drilling methods such as electrical discharge machining (EDM) or mechanical drilling: for example, holes of different diameters can be drilled without changing tools and machine downtime, and despite a high variety of types, unit costs in mass production can be minimized. Furthermore, micro drilling is a wear-free process, which proves to be extremely attractive in terms of maintenance costs.