Laser turning process

Component manufacturing in medical technology

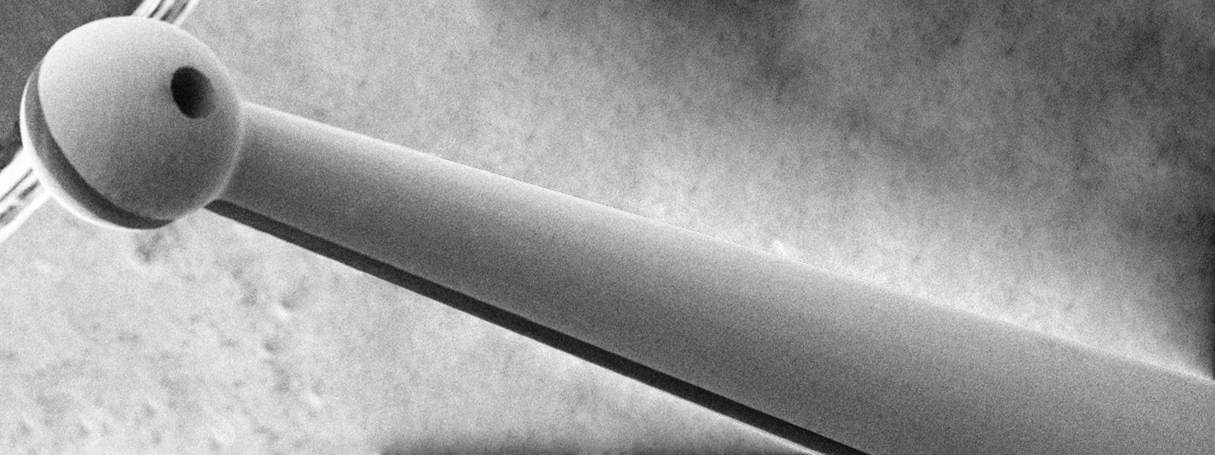

Due to their numerous advantages, innovative laser applications are gaining increasing importance in the field of medical technology. As one of the global technology leaders in the manufacturing of laser systems, GFH GmbH enables the time- and process-efficient laser turning of components, even with very small diameters, including micro forceps with ball tips for applications in medical technology, through its highly precise system technology. The turning process consists of two sub-processes: roughing (coarse machining) and finishing (fine machining). In contrast to conventional turning processes, it offers a number of advantages: In addition to contactless machining with even the smallest tool sizes, it can process virtually any material. Furthermore, GFH GmbH has significantly optimized the so-called roughing process in terms of process time and efficiency. These positive factors of the roughing process not only offset the higher time required for the finishing process but also accelerate the process time significantly. Thus, the laser turning process is exceptionally well-suited for component manufacturing in medical technology, particularly due to its optimized process time factor, dimensional accuracy, and surface quality.