Precision meets design

Innovative product solutions for universal laser machining

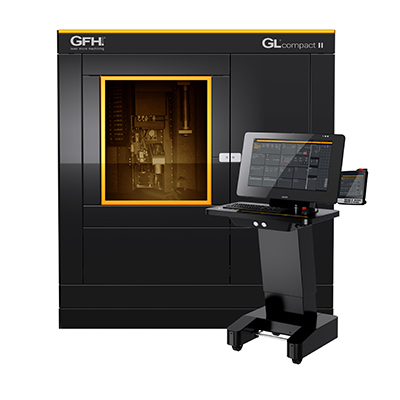

GFH GmbH already brought a smaller version of its GL.evo flexible laser machining station to market a few years ago with the GL.compact. In order to guarantee this space-saving solution for universal laser micro machining as well, the laser equipment manufacturer is offering a production solution that delivers extensive machining diversity notwithstanding its very small footprint under the name GL.compact II. Numerous further developments of the GL.evo were implemented in the compact system as well – among other things in the form of higher movement accuracy and the possibility of universal 5-axis simultaneous machining. The machine with its highly innovative design adapted to ergonomic requirements is being presented for the first time at this year’s LASER World of Photonics in Munich, hall A2, exhibition stand 552.

In addition to the highest machining precision, the fundamental concept in the development of the new GL.compact II laser system encompassed an appealing design, universal installation possibilities and an automation function for series production. The machine is versatile in application and covers the entire laser machining spectrum – from micro drilling to fine cutting and engraving to laser turning. It consistently guarantees the highest machining precision. Another objective was to achieve increased vertical integration and value creation within the company with this system, reducing supplier dependencies and offering more efficient service with shorter response times to customers. Aside from the flexible field of application, stable accuracy over the long term and the small footprint support fast amortisation of the system that comes at a comparably attractive price.

GL.compact II

In addition to the highest machining precision, the fundamental concept in the development of the new GL.compact II laser system encompassed an appealing design. Aside from the technical innovations, external factors such as design and ergonomics were taken into account in development. Thus the GL.compact II features optimal accessibility through machining doors on all sides of the machine.

Extended equipment for the greatest flexibility and accuracy

The GL.compact II was designed for 5-axis simultaneous machining, which is already standard in the high-end multifunctional GL.evo system. “We have improved five-axis simultaneous machining over the past years, optimising the repeat accuracy among other things,” explains Anton Pauli, CEO of GFH GmbH. To this end the new compact version was fundamentally optimised in terms of axis dynamics and precision through further development of the drive and guidance technology. High-precision guides ensure high repeat accuracy on all axes, and the exclusive use of direct linear motors has a positive impact on movement accuracy. A repeat accuracy of 1 µm in the X, Y and Z-directions is realised as a result. For the B and C-axes, it was reduced by a factor of 5 to 2 arcsec compared to the predecessor model.

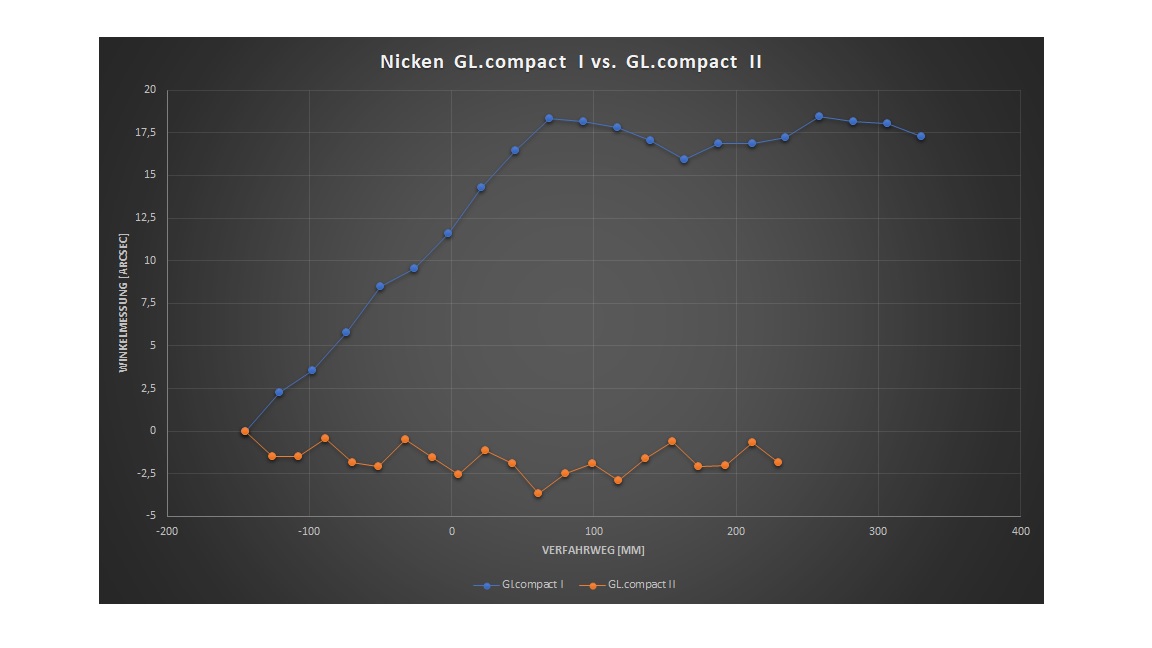

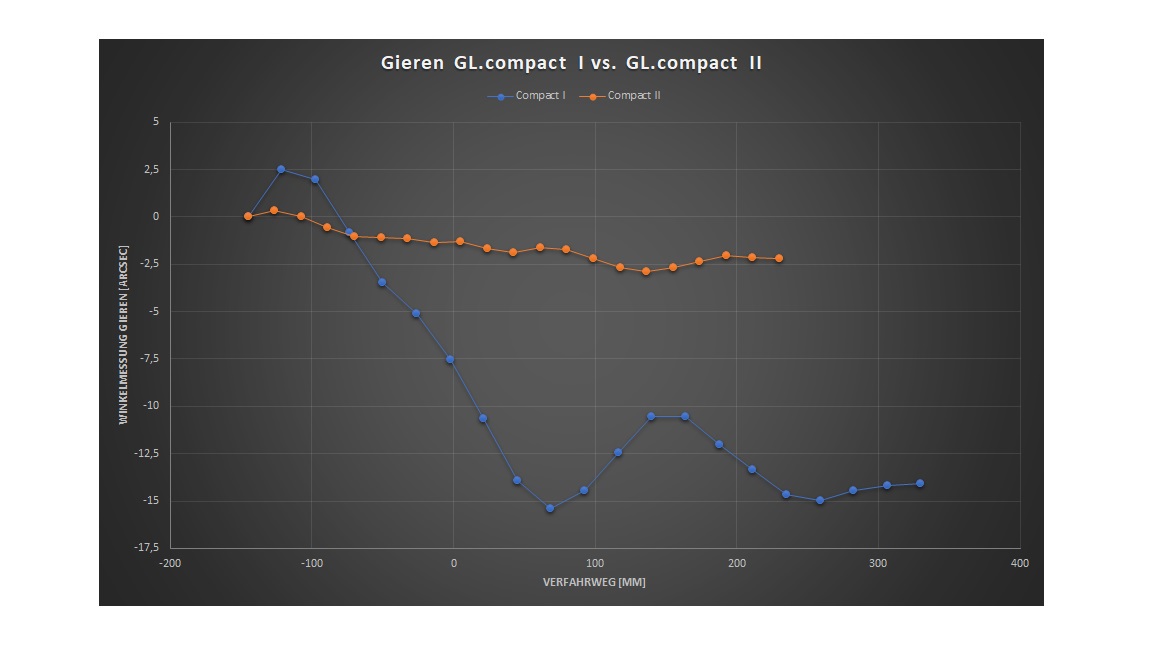

In addition to the positioning and repeat accuracy of the individual axes however, the angle accuracy in particular plays a crucial role for the precision of multi-axis machining. It was therefore emphasised during development and ultimately an improvement was successfully implemented with the new axis concept. “Compared to the previous model, we achieved a considerable angle error reduction for both pitching and yawing,” says Pauli (see the illustration “Angle error”). A new cooling concept was realised for the GL.compact II to ensure this accuracy would be stable in production over the long term. In addition to the machine base, the linear axis carriages are also made of granite, reducing the material mix and stabilising the core temperature during machining processes. All heat sources in the machine are actively cooled with water, including all axis drives. This keeps the temperature level constant from the time of start-up, and an extended warm-up time of the kinematics is eliminated, even for precise processes. With this concept, the machine is very robust in response to internal and external temperature influences and thus guarantees machining results that are stable in the long term, from the prototype to series production.

Thanks to the improved axis concept, a considerable angle error reduction for both pitching and yawing was realised compared to the previous model.

Compact design with numerous expansion options

The installation plan of the machine can be freely selected, because the footprint of the system is only 2100 mm x 1600 mm thanks to the compact design, so that accommodation even in smaller production halls is no problem. A large number of optional, interchangeable modules, with which the GL.compact II can be equipped and expanded, round off the machine concept. "Here, we consistently rely on the established advantages of Hirth gearing to keep changeover times as short as possible," explains Pauli. "Due to a changeover accuracy of < 2 µm, requalification of existing production processes becomes unnecessary."

For example, fixed or scanner optics compatible with all commercially available ultrashort pulse laser sources may be installed through the selection of optional modules. The GL.vision camera module in turn supports precise positioning of the component under the laser, including optical measurement with the resolution of a microscope. “Here we have reduced the offset between the measuring instrument and machining surface, so that longer components can now be machined on the compact system as well and the traverse paths are used more effectively,” says Pauli. Depending on the chosen optics and mounting, the machining station can process components with a length up to 200 mm in 5 axes. The optional automation function via a robot access door or quick-change component system makes it possible to swap components in seconds. With in-house machine automation development, GFH is available to its customers as the first point of contact, thereby facilitating direct manufacturer communication.

Aside from the technical innovations, external factors such as design and ergonomics were taken into account in development. Thus the GL.compact II features optimal accessibility through machining doors on all sides of the machine. The chosen frame concept offers unrivalled free movement notwithstanding the size and weight, resulting in optimal ease of use for the operator. Combined with the innovative glass design, it is not just a visual highlight with a consistent clearance but also ensures the laser and radiation safety that is important for operation. A comprehensive operating concept integrated into the machine further enhances its ease of use. The machine operator trolley featuring an ergonomic design can also be configured as an option. It is equipped with a power height-adjustable telescopic lifting column that adjusts to the operator’s height at the push of a button. The monitor angle can also be adjusted to the user’s needs.

“With the GL.compact II, we are bringing a machine to market that fully lives up to its reputation as a compact all-round model with innovative technology, a sophisticated design and ergonomic highlights,” is how Pauli sums it up.