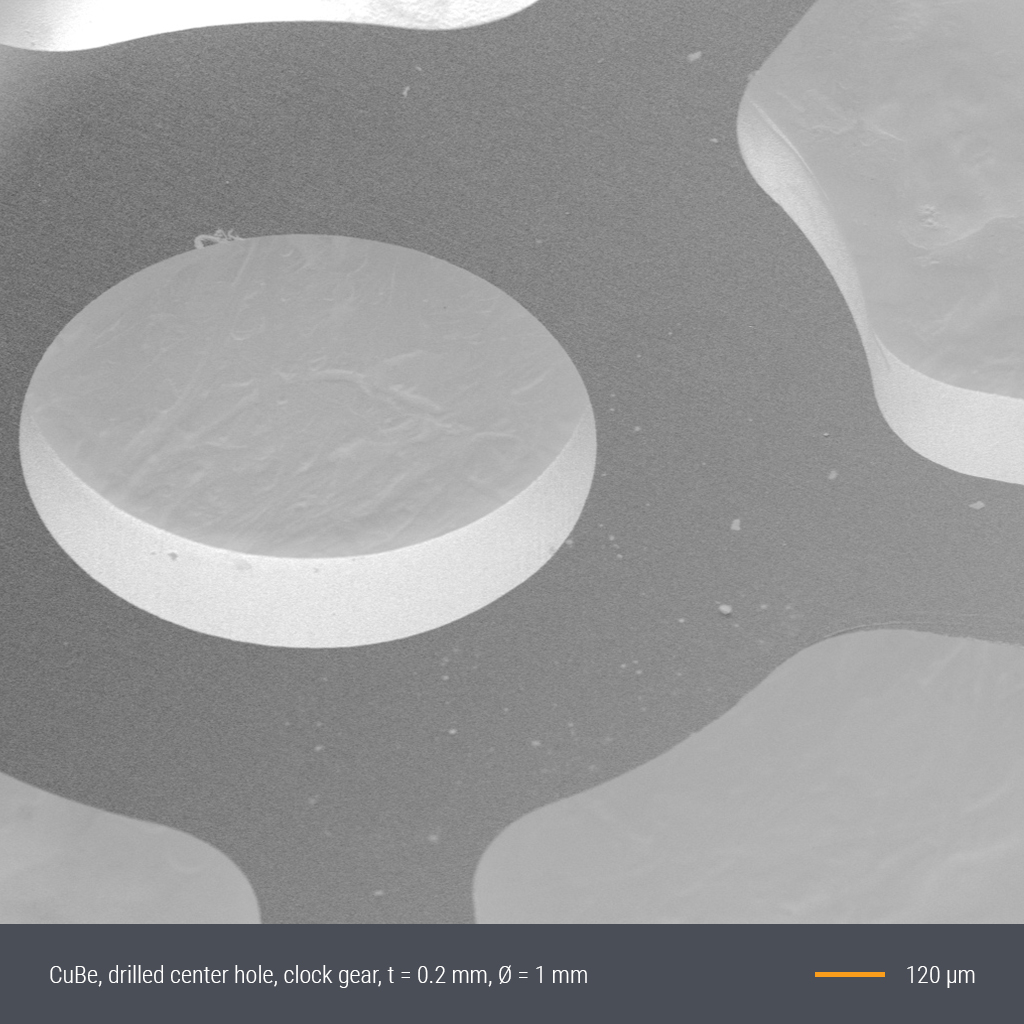

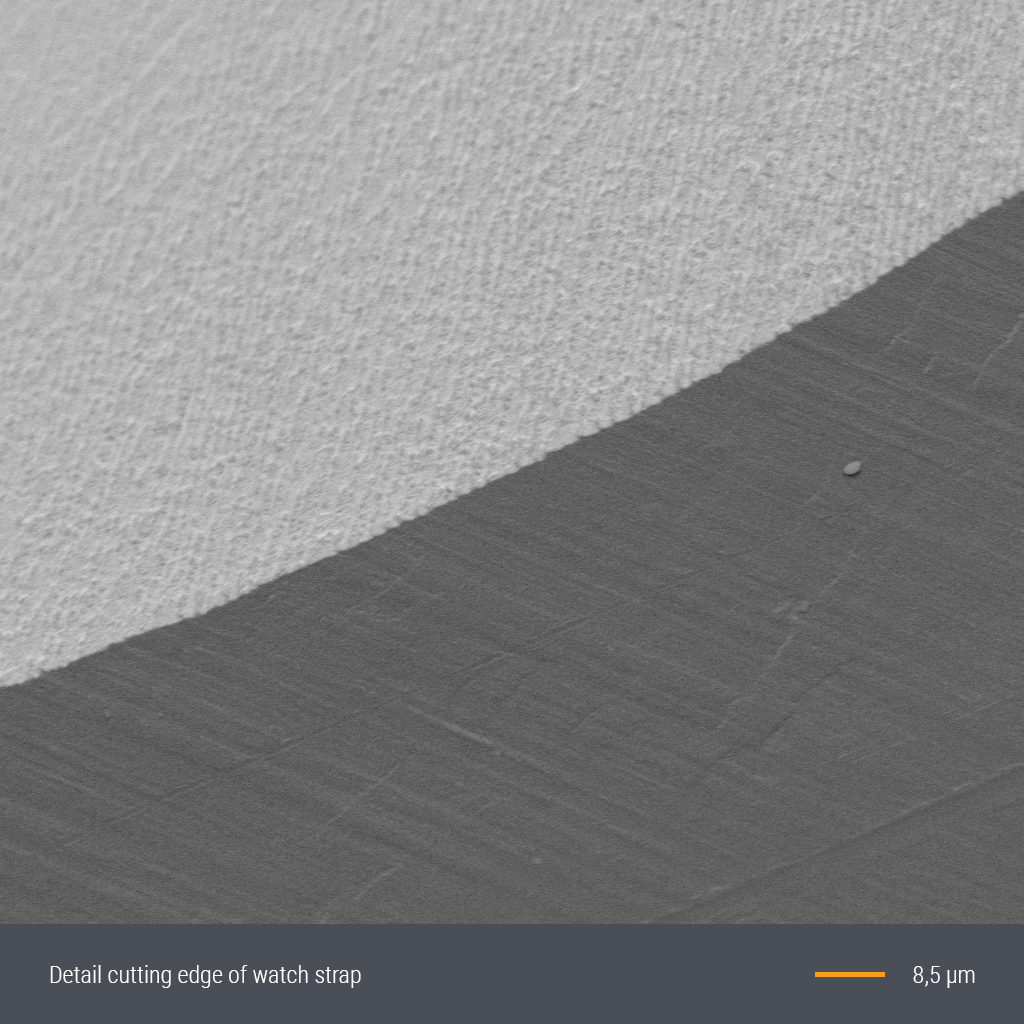

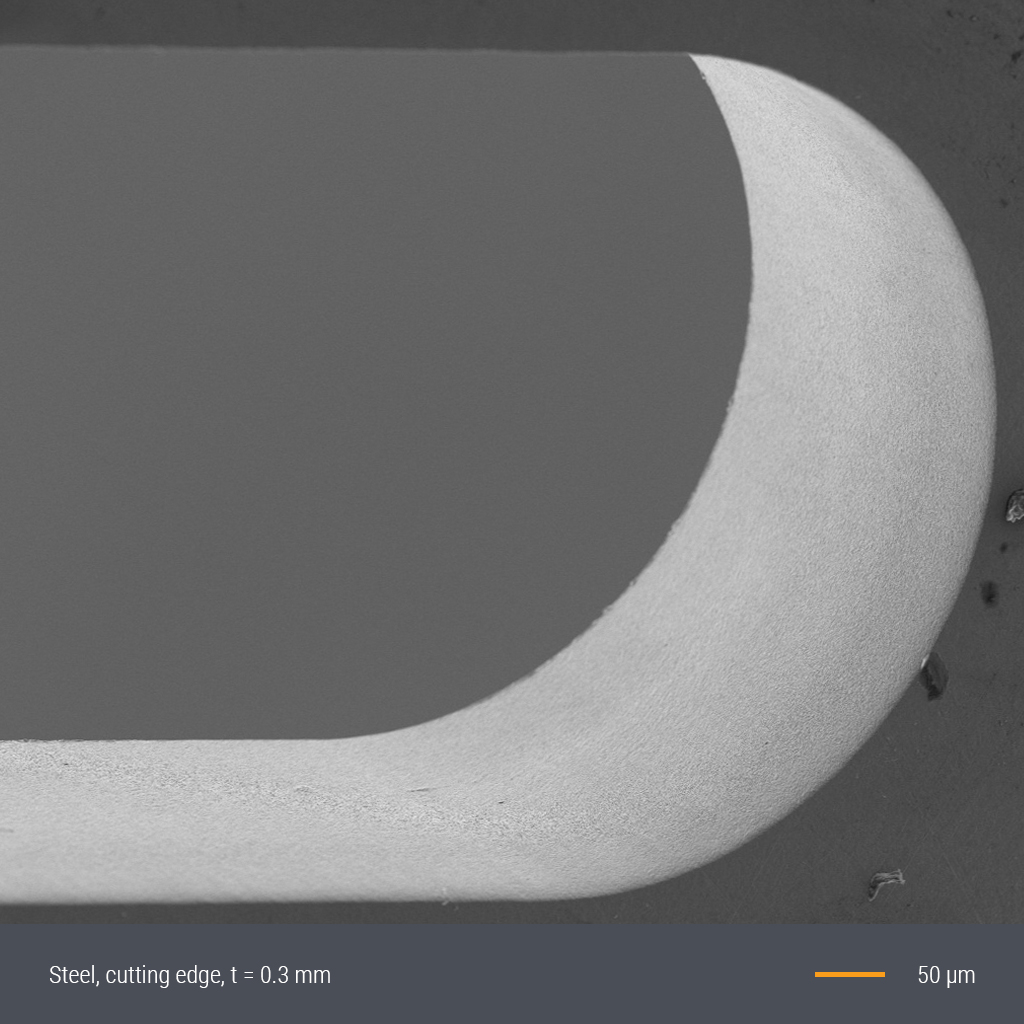

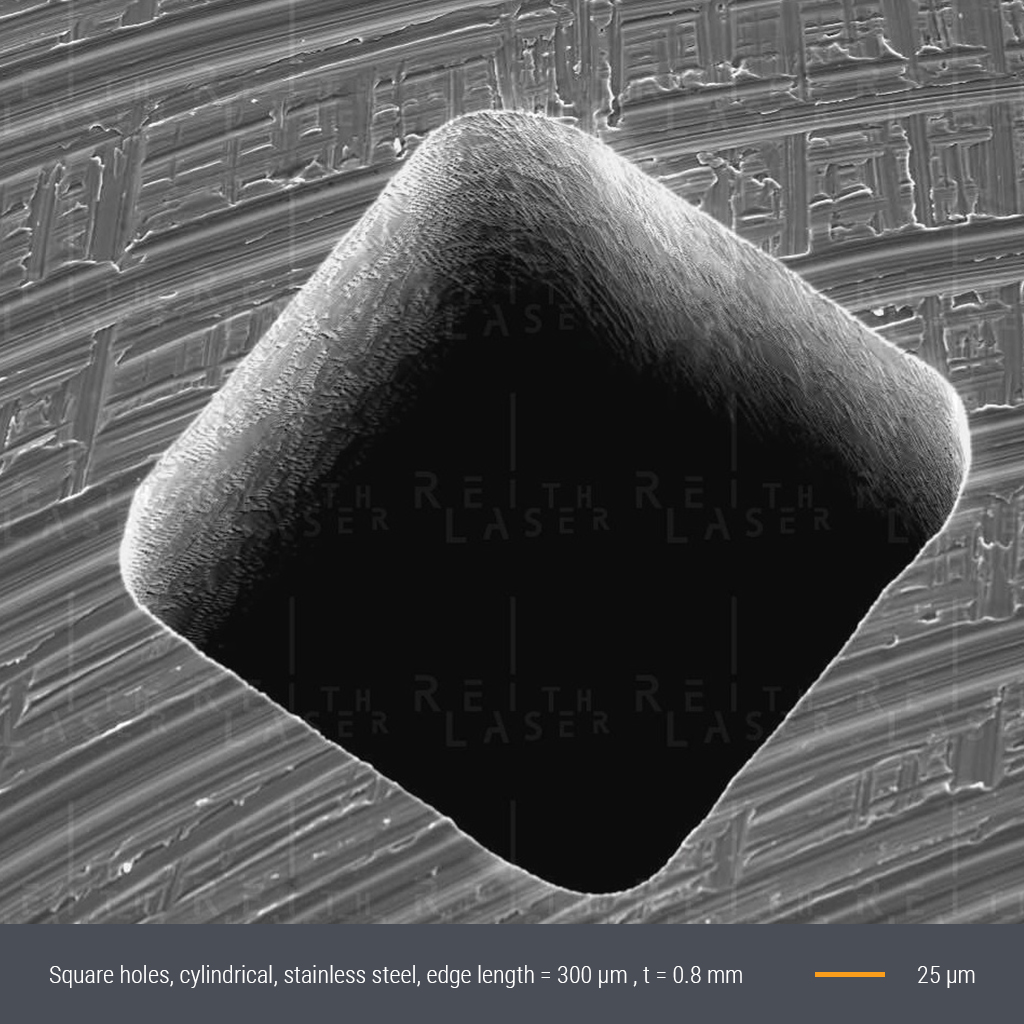

Fine cutting

In laser fine cutting with ultrashort pulse lasers, the material is vaporized in the cut seam. This prevents melting residues from being deposited on the cutting edge and having a negative impact on the result. This way, burr-free cuts can be made without negative thermal influences, which makes this process ideal for cutting small and high-precision components from all materials, even brittle-hard or temperature-sensitive materials.

In combination with the high-precision axis systems and the trepanier optics GL.trepan of our laser micro machining systems, even the highest demands on geometric tolerances can be realized and the wall angle can be adjusted to achieve perfect vertical cutting edges.