About us

The GFH GmbH is one of the global leaders and technology pioneer in designing and engineering of high precision laser micro machines with ultrafast lasers. One of the focus areas lays within the continuous development of the “tool” called laser.

One of the focus areas lays within the continuous development of the “tool” called laser. Nowadays, the laser technology is already applied for different types of processing, with lowest tolerance and no deterioration, such as: micro cutting, laser turning, laser drilling, micro structuring and micro engraving. As a result, the laser technology of GFH does not only improve the productivity of serial production but also lays the foundation for innovative production methods and future production demands.

In addition we offer a professional job shop where our clients needs are met. This production takes place in our company building with our own inhouse manufactured laser micro machines.

Series- and special machines under one roof

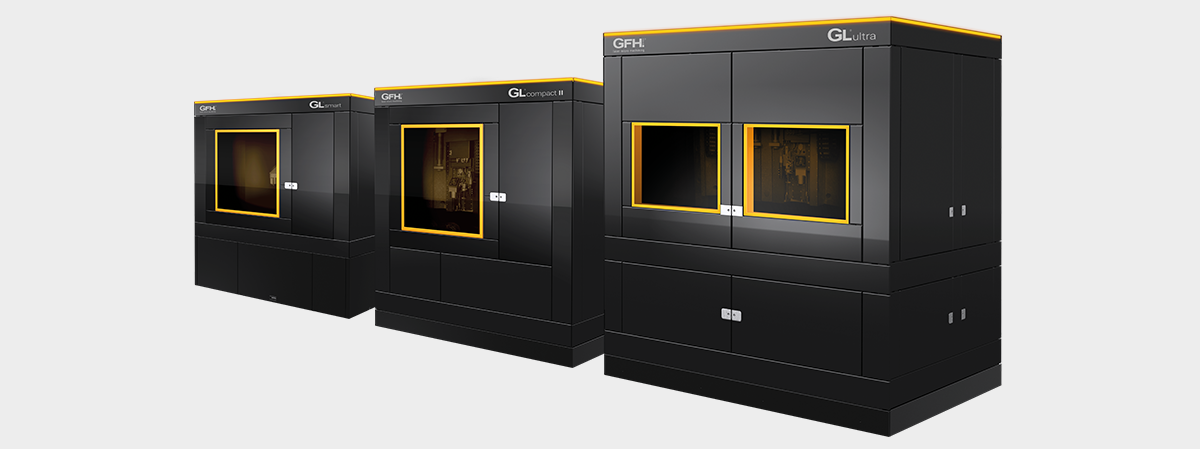

Considered the wide range of productional tasks our portfolio of laser workstations does contain various types of serial production solutions which can be individualized easily and effectively. This allows us to shorten delivery times and ensure optimal production results as well as a high planning certainty for our clients.

For very specific needs, we can draw on many years of experience in building special machines. This allows us to build a unique workstation for the customers requirements catalogue.

Support from A-Z

Throughout the development and commissioning of your very own GFH laser workstation – and beyond that – our experts will always stand by your side and help you with all questions, problems and wishes.

To exhaust all the possibilities of state-of-the-art technologies and achieve maximum performance and quality, our professional employees elaborate a manufacturing strategy in close cooperation with our client. The expertise of our team goes far beyond the pure laser technology and includes, among others, the qualification of the components and metrology.

Beyond that we supervise the custom made process from the very first feasibility study to mass production to assure that all processes are geared to each other and the final result surpasses all expectations.

Focus area

Laser micro machining includes a wide range of different processes which is constantly expanding. Our man focus and area of expertise are: micro drilling, fine cutting, ablation and laser turning.

HISTORY

25 Years of GFH GmbH – IHK Certificate of Honor

MBA, B. Eng. Florian Lendner becomes Managing Partner of GFH GmbH

GFH GmbH Honored as Top Company of Lower Bavaria 2024

Company of the Month: Our Success in the Deggendorf District

Sabato Lasertec AG becomes the exclusive sales and service partner of GFH GmbH in Switzerland

MBA, B. Eng. Florian Lendner becomes sole CEO of GFH GmbH

Dual leadership at GFH GmbH – MBA, B.Eng. Florian Lendner appointed Managing Director

Expansion of the GL machine series with the GL.smart, GL.compact II, and GL.ultra

20 years anniversary and inauguration ceremony of the new building

GFH moved into the new building

Installation of the first industrial femtosecond laser with 40Watt

Partial sale of the precision production to Liebherr and focus on laser micro machining

Market launch of the GL.compact laser micromachining system

New Building 2 – Expansion of mechanical engineering production space by 2,500 m²

Launch of series production for injection parts

Change the corporate name of the GFH organisation for production process planning mbH Research & development Prof. Dr.-Ing. Hans-Joachim Helml to GFH GmbH

Summary of the GFH activities and introduction of three business sectors F&E, precision production and special machine manufacturing

Mr. Prof. Dr.-Ing. Hans Joachim Helml gives up the operational business. The management of the GFH mbH is taken over by Mr. Dipl.-Ing. (FH) Anton Pauli

Inauguration of the new GFH building in Deggendorf, Großwalding

Extension of activities in the divisions: special machine design and laser materials processing

Extension of the automobile industry market and their suppliers as well as of the micro technology sectors

TRW sells the Diesel Division to Delphi automotives

Spin-off from the operation establishment Delphi Diesel Systems Deggendorf to a GmbH. Extension around the main emphasis: ECM, test attachment, construction, tool and prototype construction

Attitude of the first two employees. Over a period of 18 months 5 other engineers, 5 masters and technicians and 5 supporting employees followed

Of Lucas Variety Systems was taken over from TRW. Extension around the main emphasis: Laser, EDM, HEG, measurement

Foundation of an operation establishment by Lucas Variety Systems through the initiative by Prof. Dr.-Ing. Hans Joachim Helml Emphasis: Process development