GL.compact II laser machine

The compactly constructed version GL. compact II offers besides maximum machining precision an attractive design, universal installation options and an automation function for series production. The laser machine covers the entire spectrum of laser processing from micro-drilling to fine-cutting and removal. It has been designed for the highest accuracy requirements in the smallest installation space. Besides the machine base, the slides of the linear axes are made of granite, which guarantees a reduced material mix and which stabilizes the core temperature during the machining processes. All heat sources in the machine, including the axle drives, are actively cooled with water. This concept offers a very robust behaviour to internal and external temperature influences and thus guarantees a long-term stable machining result.

High-precision mechanical guides in combination with linear drives and highly rigid kinematics improve the angular errors of each individual translational and rotational axis. As a result, both nodding and yawing were improved by a factor of 5 compared to the previous model.

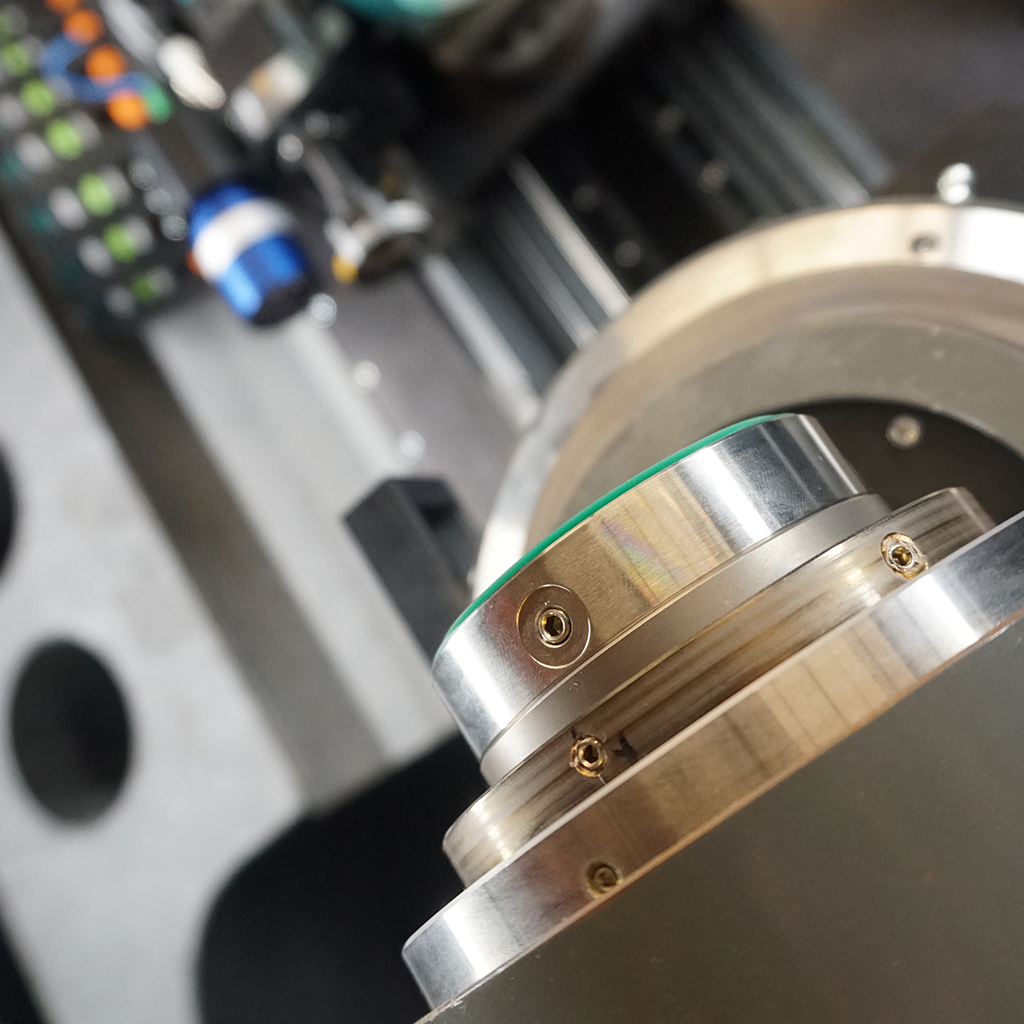

Numerous optional, interchangeable modules, which can be used to equip and expand the GL. compact II, round off the machine concept. The established advantages of Hirth-gearing are therefore consistently relied on in order to keep the changeover times as short as possible. A changeover accuracy of <2 µm makes requalification of existing production processes superfluous.

HIGHLIGHTS

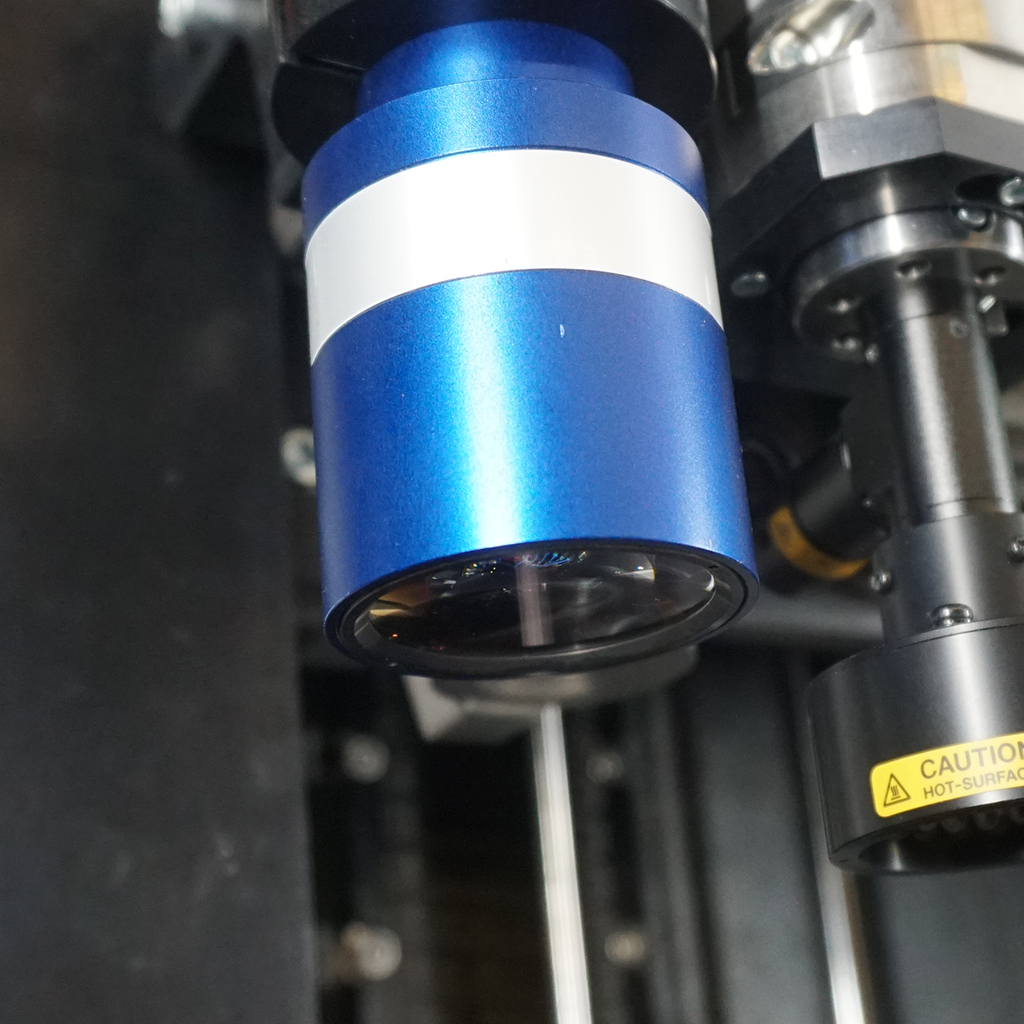

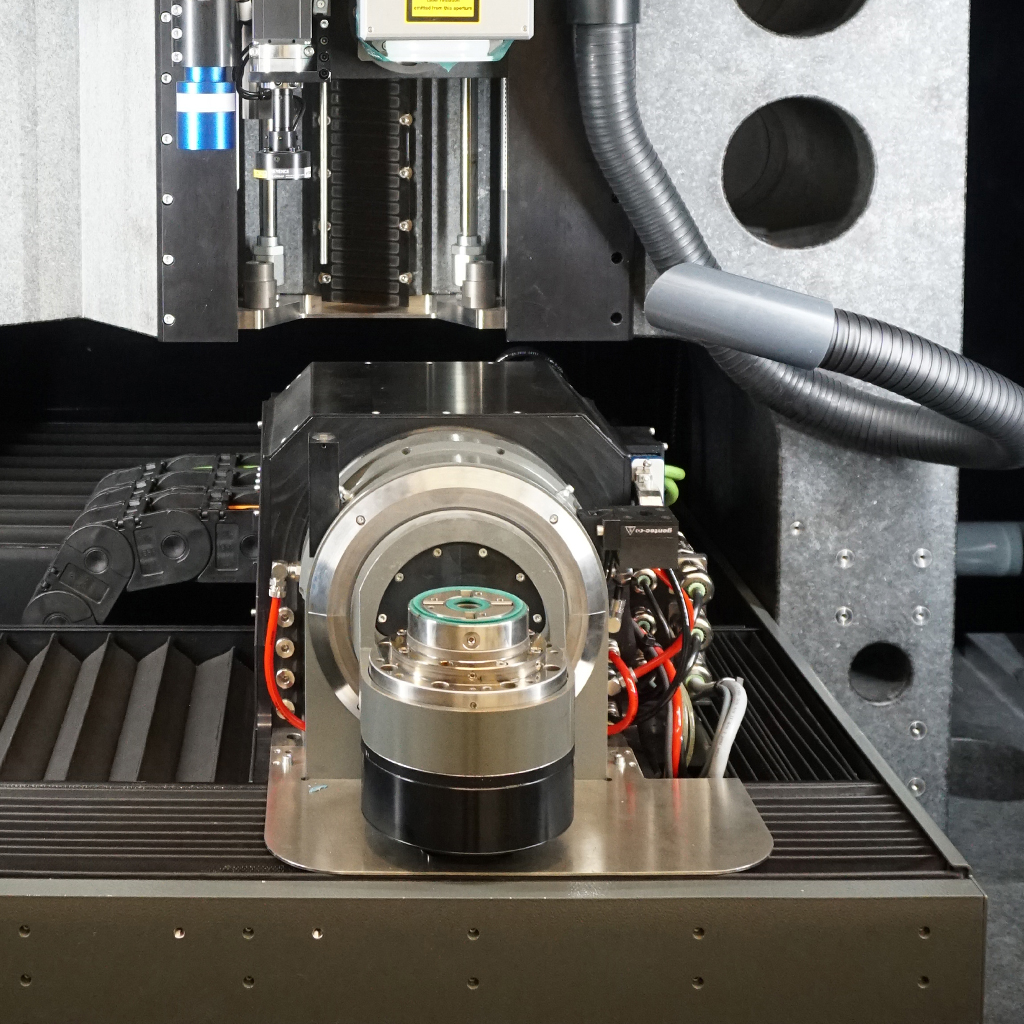

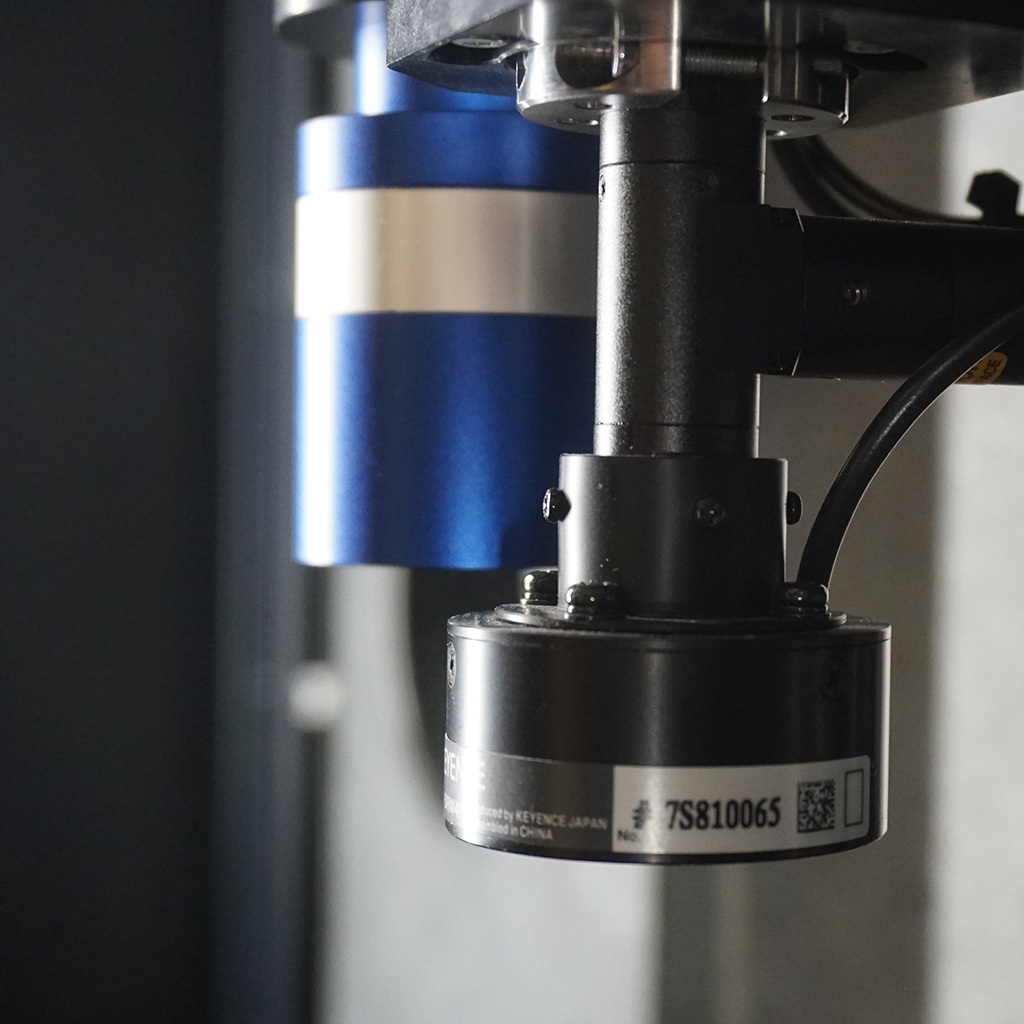

PRODUCT IMAGES

TECHNICAL DETAILS

| Axis | X | Y | Z | B | C |

|---|---|---|---|---|---|

| Axis type | linear | rotary | |||

| Drive type | direct drive | torque drive | |||

| Bearing | profiled rail guide | M&V-guidance | radial thrust bearings | cross roller bearings | |

| Travels [mm] | 400 | 390 | 360 | +/- 110° | endless |

| Speed | 30 m/min | 200 U/min | 500 U/min | ||

| Acceleration | 5 m/s² | 160 1/s² | 220 1/s² | ||

| Repeatability | 1 µm | 2 arcsec | |||

| Positioning accuracy | 1,5 µm | 2 µm | 5 arcsec | ||

| Perm. comp. weight | 20 kg | 2 kg | |||

| Clamping set-up | clamping system | ||||

| Sound pressure level | ≤ 70 dB | ||||

| Dimensions [mm] | D =1 536 / W = 2036 / H = 2219 – without supply unit | ||||

| Total weight | 3700 kg without internal control cabinet | ||||

HARDWARE MODULES

All GL.compact II modules.